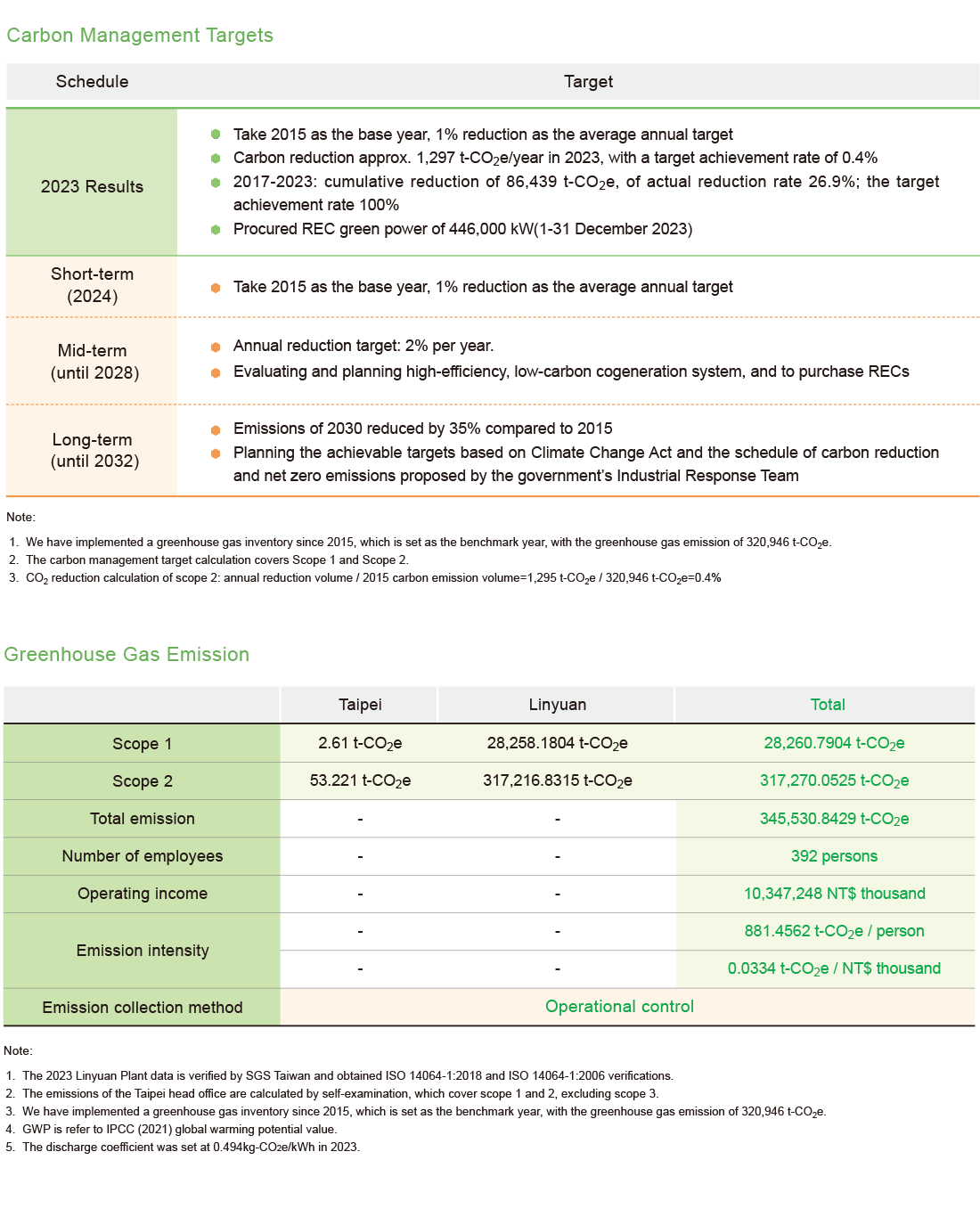

Energy Saving and Carbon Reduction Commission

In order to promote the energy saving measures in all factory sites, OUCC established a cross-departmental Energy Saving and Carbon Reduction Commission and sets out the “Procedures for the Organization of Energy Saving and Carbon Reduction Commission”and other mechanisms. Working meetings are held on a quarterly basis to ensure the goals are reached. A variety of energy saving practices are implemented to achieve the goals of greenhouse gas reduction and even the net zero emissions.

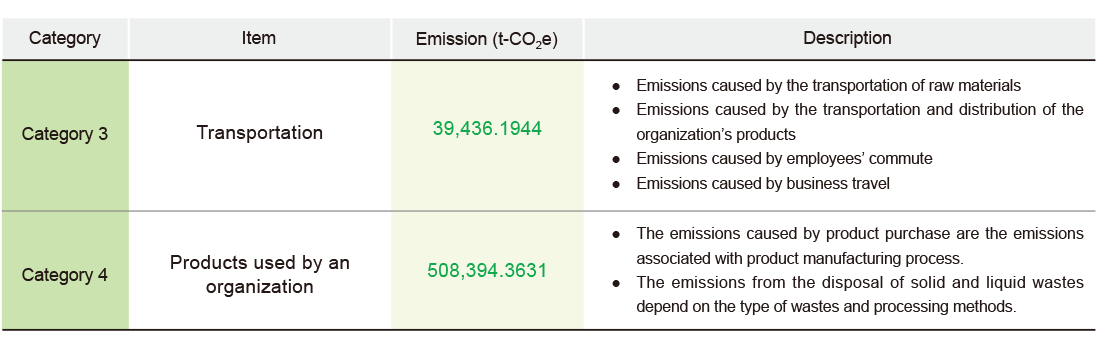

Emission of Value Chain

Note: The 2023 Linyuan Plant data is verified by SGS Taiwan and obtained ISO 14064-1:2018 verification.

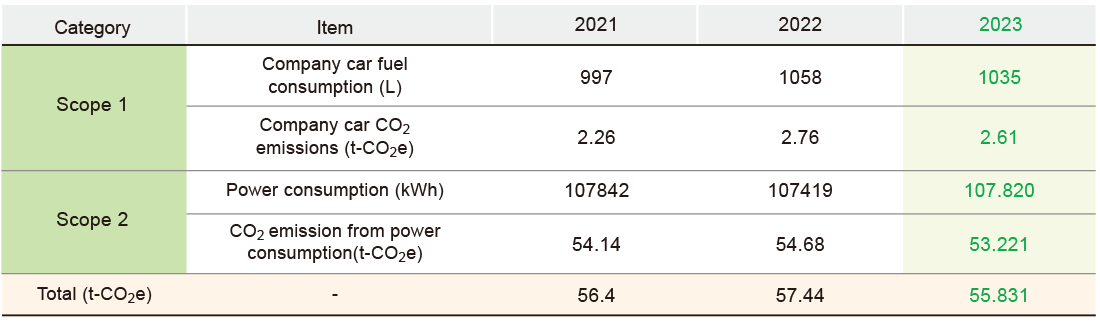

Greenhouse Gas Emission (Taipei Head Office)

Note: The above data is converted in accordance with the annual average unit price of the "Oil price data management and analysis system" of the Department of Energy MOEA Office (https://www2.moeaboe.gov.tw/oil102/oil2017/newmain.asp).

https://www2.moeaboe.gov.tw/oil102/oil2017/newmain.asp

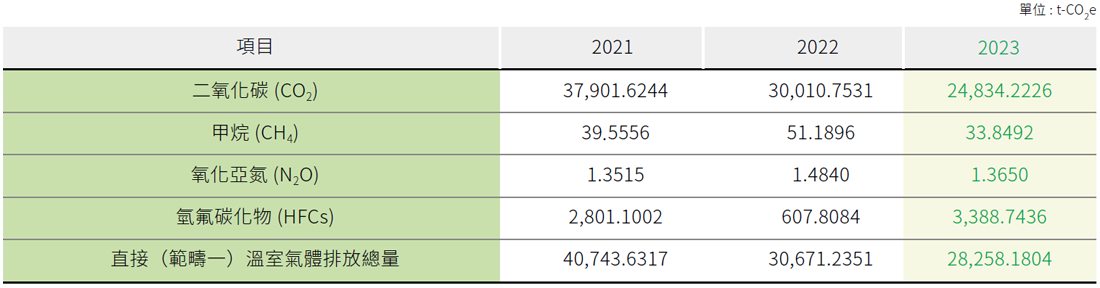

Greenhouse Gas Emission (Linyuan Plant)

Note:

1. SF6、PFCs、NF3 emissions are0 t-CO2e

2. We have implemented a greenhouse gas inventory since 2015, which is set as the benchmark year, with the greenhouse gas emission of 320,946 t-CO2e

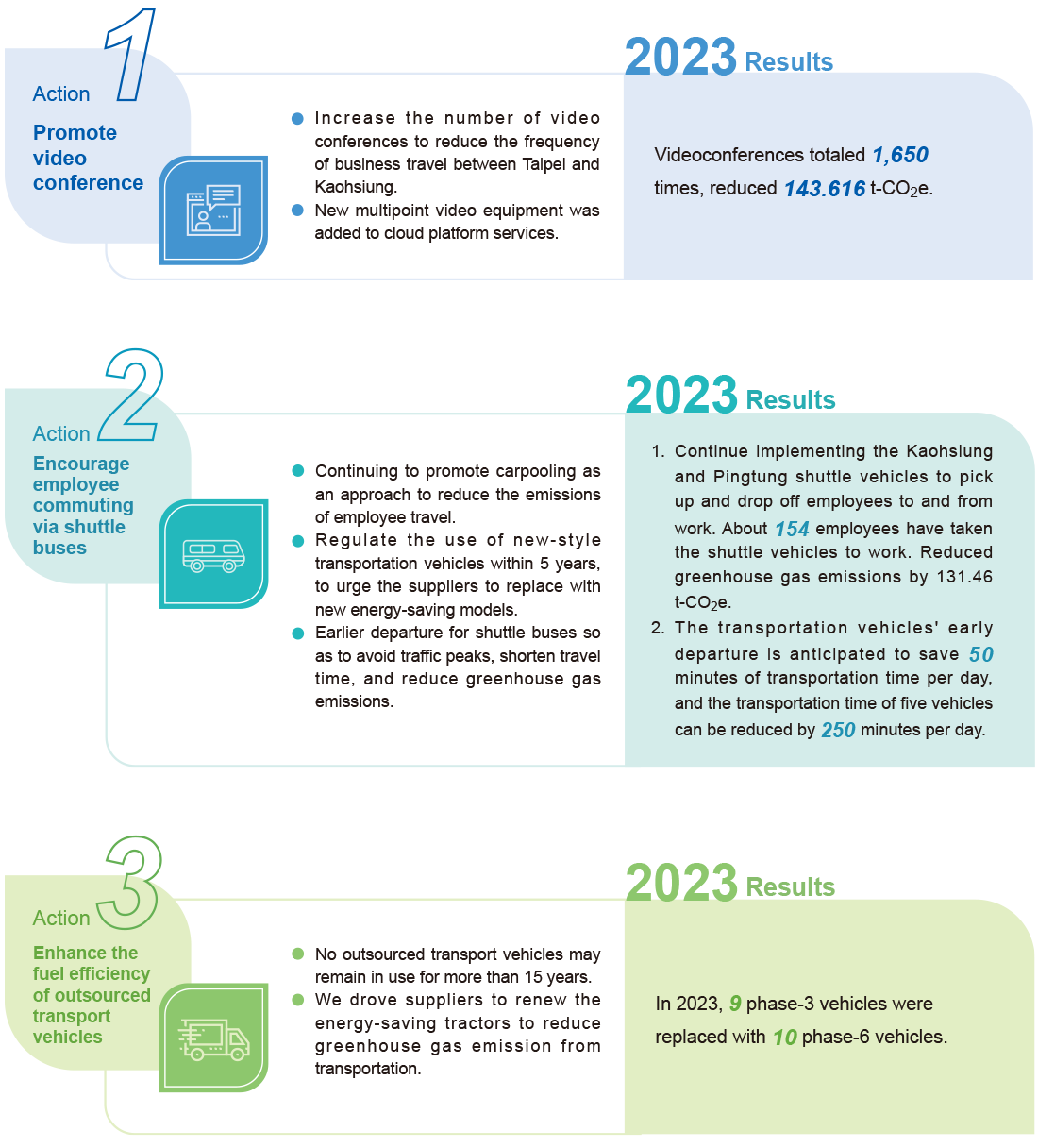

The Mitigation of Transportation Emission

To save energy and reduce carbon emission, we encourage employees at the Linyuan plant, the main manufacturing base of the OUCC, to take use of the company shuttle buses, or to join the carpool system for commuting, so as to cut down on the use of vehicles and reduce the indirect emission of greenhouse gases.

Stakeholders Contactors

- Mr. Chen/Ms. Chang

- E-mail: ESG@oucc.com.tw

SHE Contactors

- Mr. Yeh/Mr. Wu

- E-mail: she@oucc.com.tw