Resources Recycling

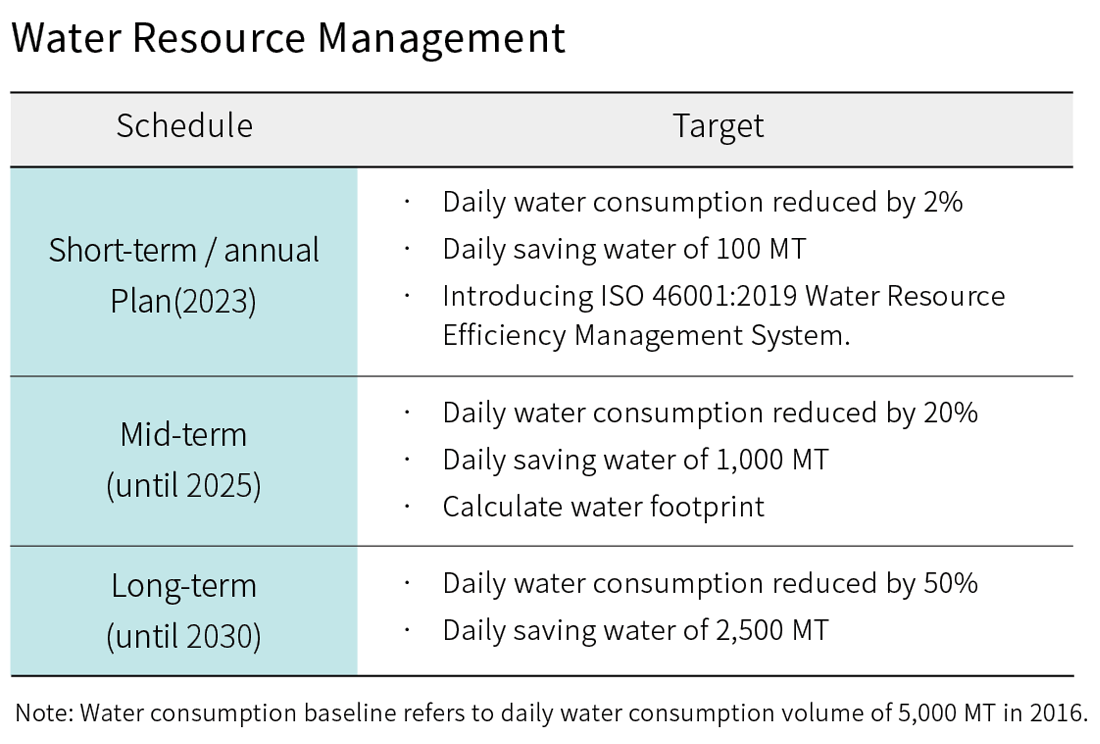

Water Resource Management

Note: Water consumption baseline refers to the daily water consumption volume of 5,000 MT in 2016.

Note: Water consumption baseline refers to the daily water consumption volume of 5,000 MT in 2016.

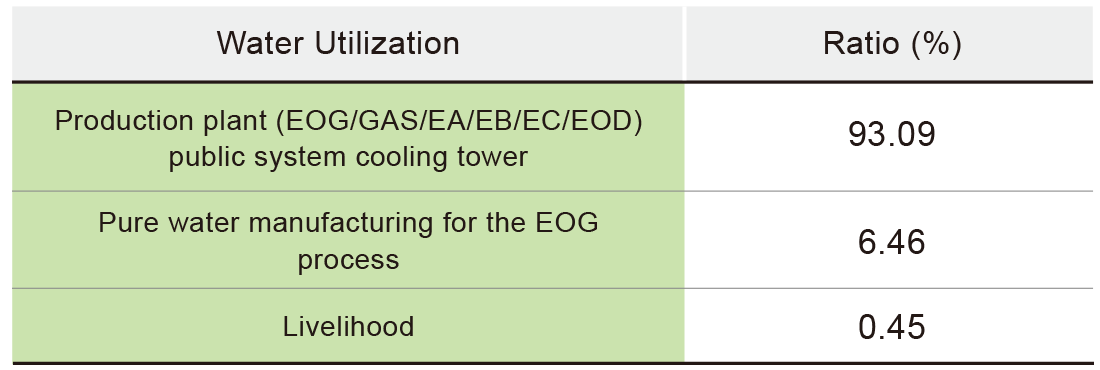

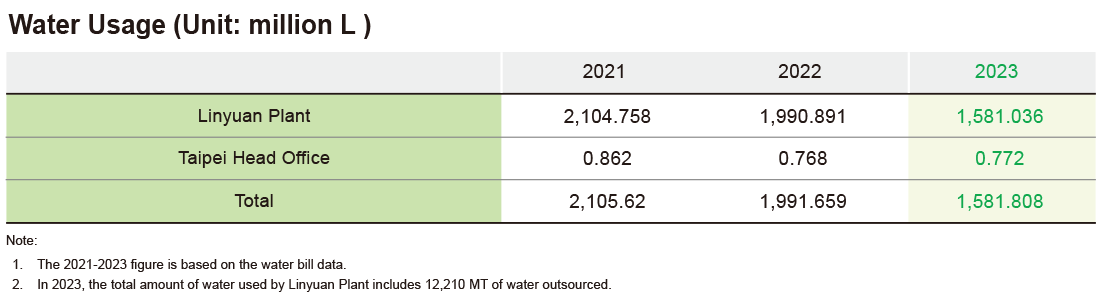

Water Resource Usage

OUCC Linyuan Plant uses the water from the Fengshan Reservoir rather than the areas suffering from water shortage. The water is treated before use. The plant is located at the industrial park, so the wastewater is discharged into the industrial sewers with no risk of pollution to the water source.

To cope with the risk of a water shortage or floods caused by climate change, we have formulated a comprehensive water resource management plan in cooperation with the local government and have also set water resource management objectives to handle emergencies (when implementing water restriction measures, an external water purchase mechanism will be activated if necessary, otherwise the factory’s operation loading will be reduced), water conservation measures, and introduce the ISO 46001:2019 Water Resource Efficiency Management System in 2023 to improve water use efficiency.

Relevant measures also include:

- The plant regularly records the cumulative value of the tap water meter (industrial raw water) and declares the following: weekly tap water consumption declaration to the Industrial Development Bureau’s Drought Emergency Response, monthly and annually declaration of water consumption and water resources management information, and annual flowmeter calibration for each water-consuming facility at the plant site.

- Continue to promote improvement projects in manufacturing process and technology: invested NT$68 million to build a wastewater recycling system in the Linyuan plant. The production capacity for reclaimed water is 1,000 MT per day, and the wastewater recovery rate is up to 70%, which can be used for cooling water tower replenishment.

- In 2023, the total reclaimed water production was about 197,723 MT/year (about 542 MT/day), and the wastewater recovery rate was about 55.1%. In addition, OUCC also responded to the willingness survey for the usage of recycled water, aiming at the utilization of 1,500 MT/day of recycled water and 50% of reclaimed water.

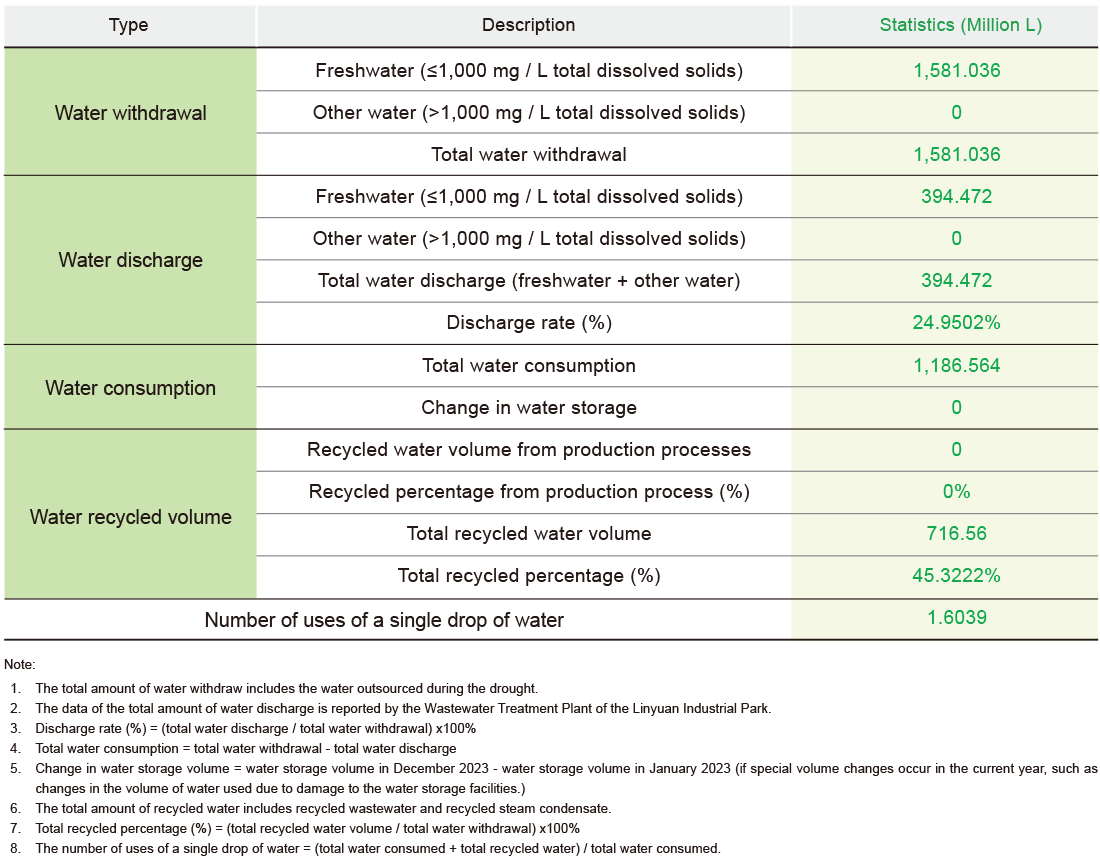

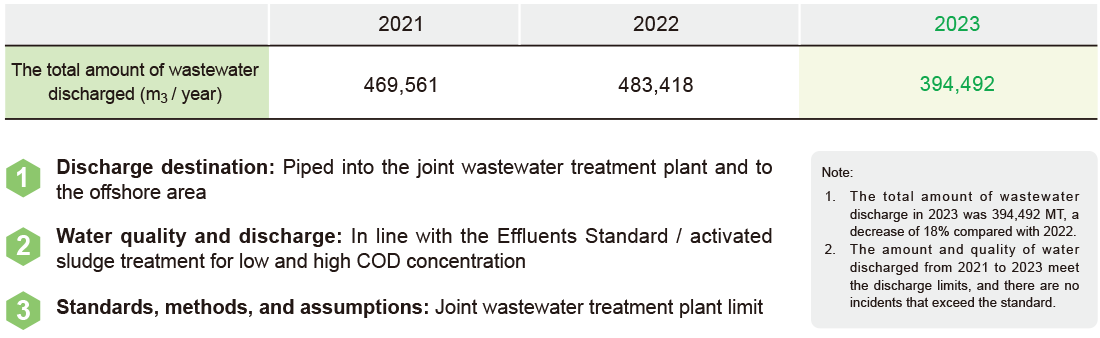

The Amounts of Total Water Intake, Waste (Polluted) Water Discharge Disclosed Voluntarily or Upon Legal Request

Water Recycling Measures

We strive to implement the water resources management mechanism in the plant premises through innovative technologies to improve the efficiency of water resource usage and reduce the environmental risks of water shortage and water resource recycling. In 2023, the volume of purchased steam totaled 518,800 MT, and the recycled condensate of 518,800 MT (calculated from 100% of outsourced steam.) The recycled condensate was mainly used as boiler water feeding and supply, with minor used as water supply for the cooling towers.

Passed the inspection by the National Cheng Kung University Research and Development Foundation in 2023. The water recovery rate (excluding circulation volume in the cooling water tower) in 2022 reached 79.5%, and the water consumption fee was reduced by NTD 169,144.

The RO process produces very pure water of high economic value, along with the wastewater of high ionic concentration as well as high COD. RO concentrated water is usually mixed with other low-concentration wastewater in the general water recycling systems, which provides the difficult-to-dissolve organic substance the access to the water environment.

In view of the effect of water quality on the environment, OUCC has been the first in the industry to introduce ABR technology for the treatment of concentrated wastewater from the RO process, reducing COD and other environmentally harmful substances, to fulfill our environmental responsibility.

Wastewater Treatment & Discharge

The chemical plant wastewater contains incompletely reacted raw materials, and the media of solvents. Any wastewater or liquid waste produced in the manufacturing process that has not been properly treated would be a serious hazard should it be discharged into the environment.

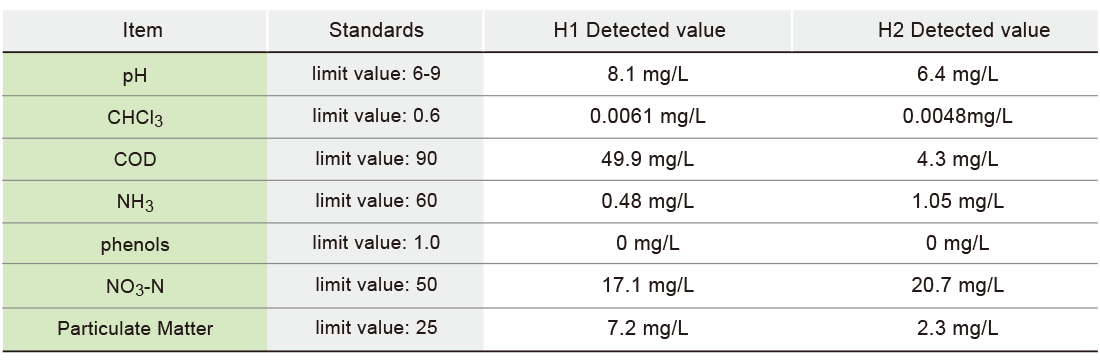

In this regard, the OUCC abides by the "Procedures for OUCC production process wastewater discharge," stipulating emission limits of COD<90ppm and SS<25ppm. The total treated wastewater is piped into the Industrial Park Joint Wastewater Treatment Plant. The initial rainfall (about 30 minutes) is collected in a storage tank, and then passed into the wastewater treatment plant for further processing. The wastewater discharge meets the limits in 2023.

Effluent Quality Test

Wastewater Discharge

Stakeholders Contactors

- Mr. Chen/Ms. Chang

- E-mail: ESG@oucc.com.tw

SHE Contactors

- Mr. Yeh/Mr. Wu

- E-mail: she@oucc.com.tw