EG Products

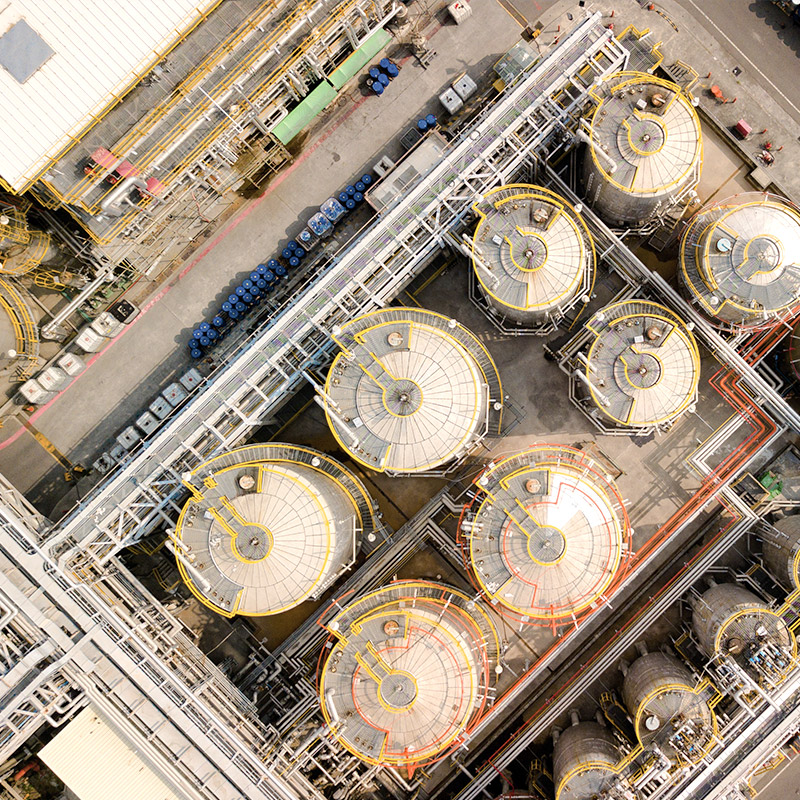

Ethylene glycol is the core product of OUCC. Since the construction completion in 1978, and the subsequent debottleneck improvememnts, the annual output of ehtylene glycol plant has reached more than 300,000 tons. The products are mainly used by domestic polyester manufacturers and exported to Asian and other regions as required.

Given the rapid expansion of polyester production capacity in mainland China, and the insufficient local output of ethylene glycol, the ethylene glycol in China remains to rely primarily on imports to fill the gap. Hence, OUCC actively engages in the business of refined ethylene oxide and the development of ethylene oxide derivatives, and jointly established with the Far Eastern New Century Corporation a glycol ethylene plant in China, with annual output of 500,000 tons and operation launch at the end of 2015, to further consolidate its core business.

In line with environmental protection policies, the carbon dioxide recovered and ethylene oxide are made into ethylene carbonate, which is used by the down-stream polycarbonate products suppliers. Purified liquid carbon dioxide can be used in various domains, such as the industry, electronics, food, and freezing.

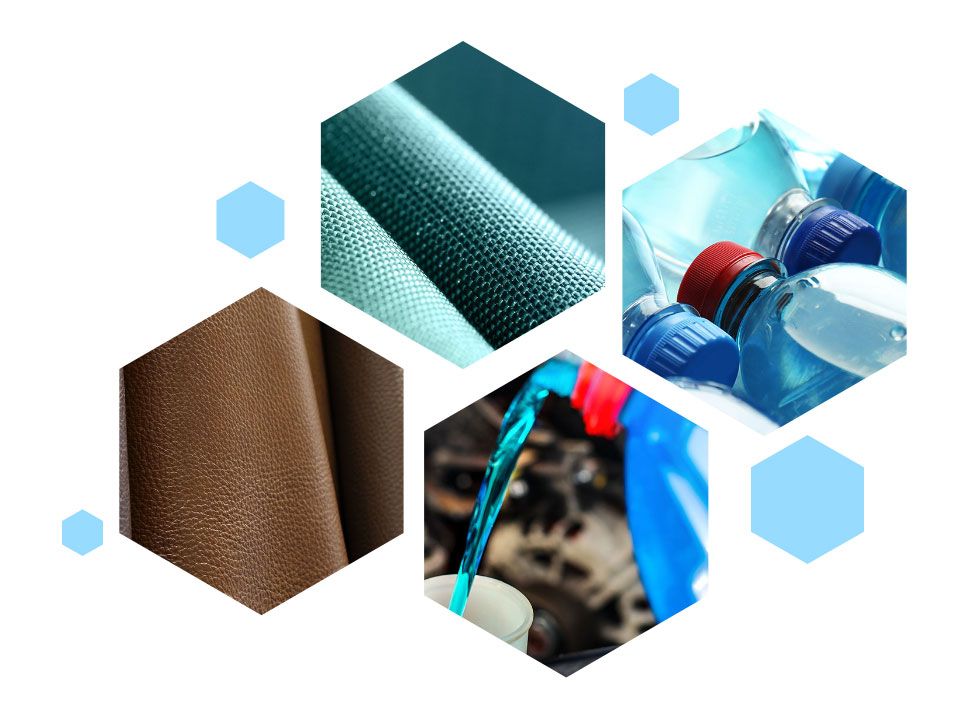

MEG

Raw materials for polyester fiber, antifreeze, dehumidifier, engineering plastics, PET bottles and brake fluid.

DEG

Dehumidifiers, lubricants, leveling agents, solvents, grinding aids and unsaturated and polyol raw materials.

TEG

Application of dehumidifying agent, solvent and polyol.

EO

Raw materials for ethylene glycol, glycol ether, ethanol ether, non-ionic surfactants and disinfectants.

Product specification

According to the ISO9001 Quality Management System, the raw materials, packaging materials, and finished products are strictly controlled, with professional testing equipment and personnel set up for the quality assurance, so to provide customers with high-quality products.

| Items | MEG | DEG | TEG | |

|---|---|---|---|---|

| Specific gravity (20/20℃) | 1.1151-1.1156 | 1.117-1.12 | 1.124-1.126 | |

| IBP ℃ | at 760 mm Hg | >196 | >242 | >280 |

| DP ℃ | at 760 mm Hg | <200 | <250 | <295 |

| Acidity,Wt% as HAc ﹪[MAX] | 0.005 | 0.005 | 0.005 | |

| UV Trans. ﹪[MIN] | 220 nm | 70 | ||

| 250 nm | 80 | |||

| 275 nm | 90 | |||

| 350 nm | 98 | |||

| Total Iron PPM [MAX] | 0.07 | |||

| Aldehyde PPM [MAX] | 10 | |||

| Color Pt-Co unit [MAX] | 5 | 15 | 25 | |

| Chlorides | None by test | |||

| MEG ﹪ [MAX] | 99.8[Min.] | 0.2 | ||

| DEG ﹪ [MAX] | 0.05 | 99.5[Min.] | ||

| TEG ﹪ [MAX] | 0.25 | 99.5[Min.] | ||

| Water, Wt ﹪ [MAX] | 0.08 | 0.1 | 0.08 | |

| Water Solubility | Miscible | Miscible | ||

| Ash Wt ﹪ [MAX] | 0.005 | 0.005 | 0.006 | |

| Odor | Mild, Practically none | Mild | ||

| Suspended Matter | Free | Free | ||