Environmental Prevention Mechanism

OUCC actively takes various measures to reduce pollution emissions from its factories and facilities, and through rigorous management mechanisms, minimize the actual or potential negative impacts on the local community. We adopt innovative technology to establish a production PI system to monitor the status of the plant operation sites. This real-time monitoring system for environmental data of the plant allows employees to monitor the operation of both production and environmentally protective equipment simultaneously, ensuring equipment availability and compliance with the relevant environmental regulations.

PI allows faster detection of cumene vapors being leaked from a nearby factory. Personnel can now control the air quality without delay and activate counter responses. Incoming air is cut off by the control room and inside air is recirculated through an activated carbon filter. Workers wear gas masks when working outdoors to prevent the inhalation of cumene vapor. Contact will be made with the nearby factory as soon as possible to request that corrective action be taken.

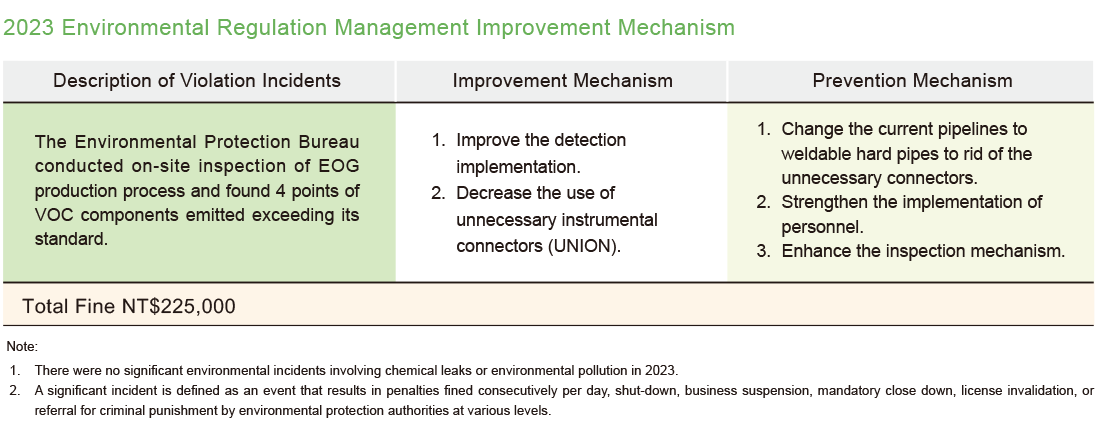

Air Pollution Control and Prevention

The Linyuan plant has acquired 7 Fixed Pollutant Operator Permits from the Environmental Protection Bureau of Kaohsiung City Government in accordance with Article 24 of the Air Pollution Prevention Act. According to the content of the permits, pollutants are tested and reported regularly. The main air pollutant emissions are: Volatile Organic Compounds (VOCs), Ethylene Oxide (EO), and ammonia.

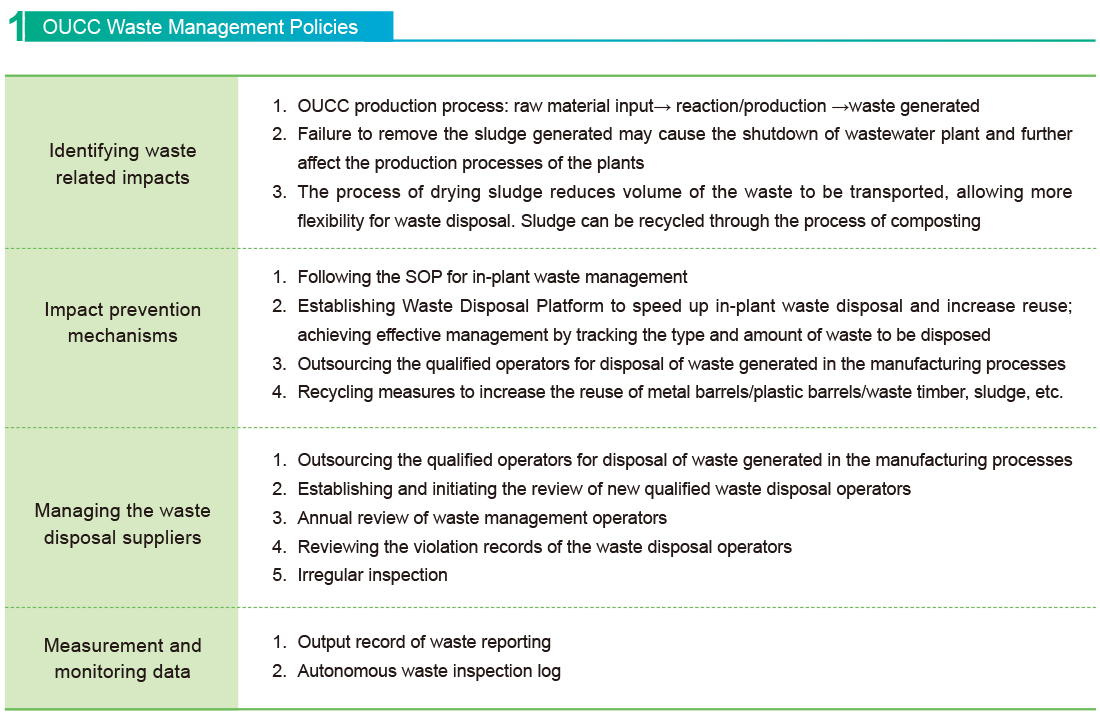

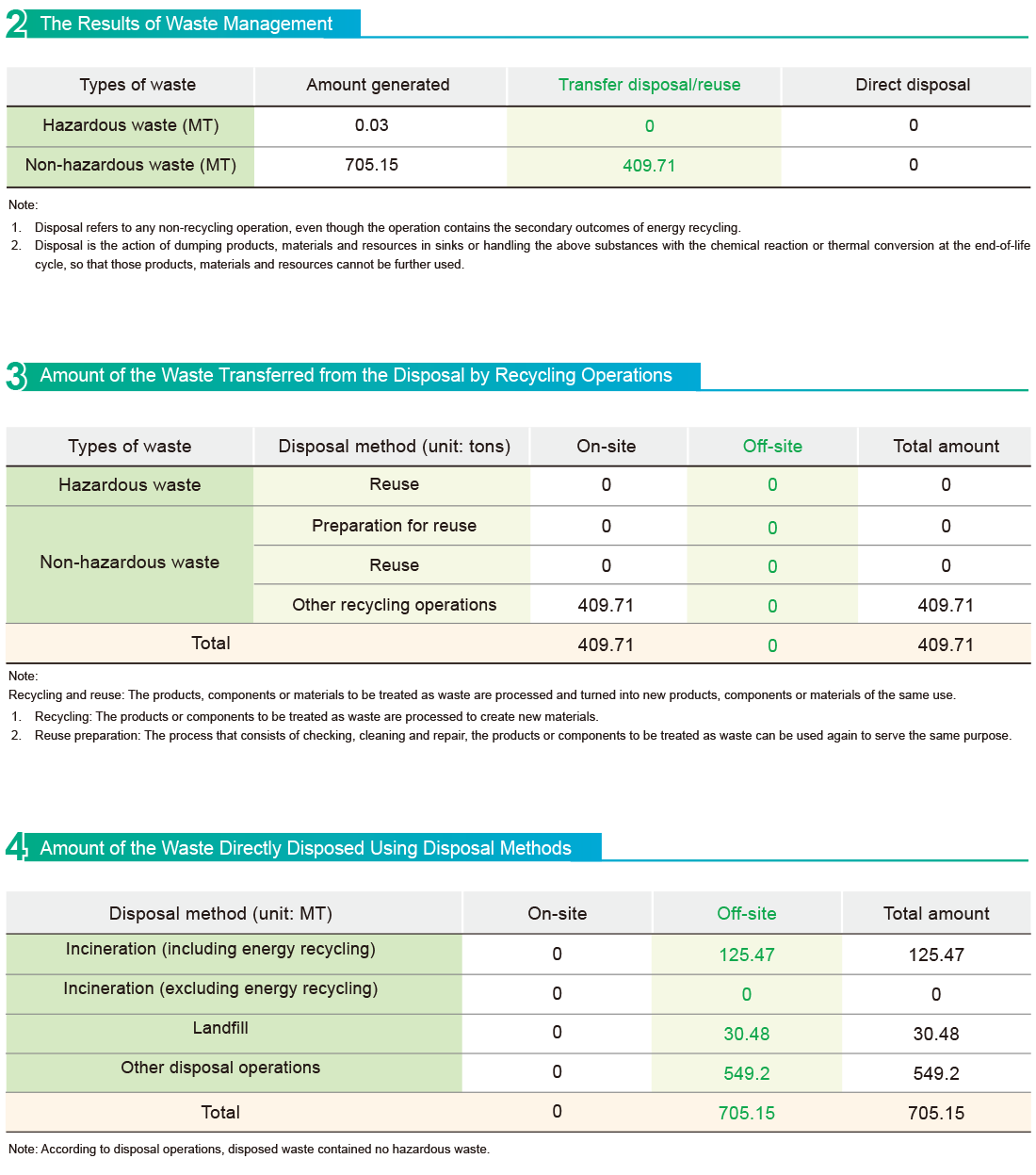

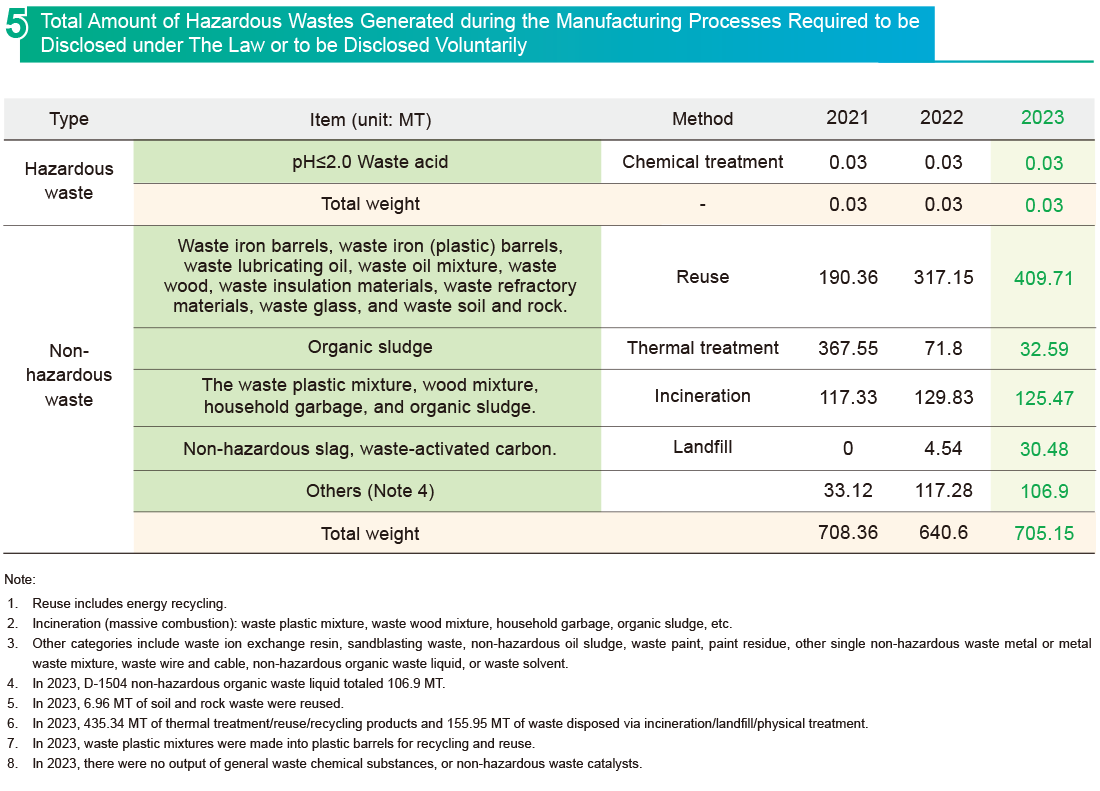

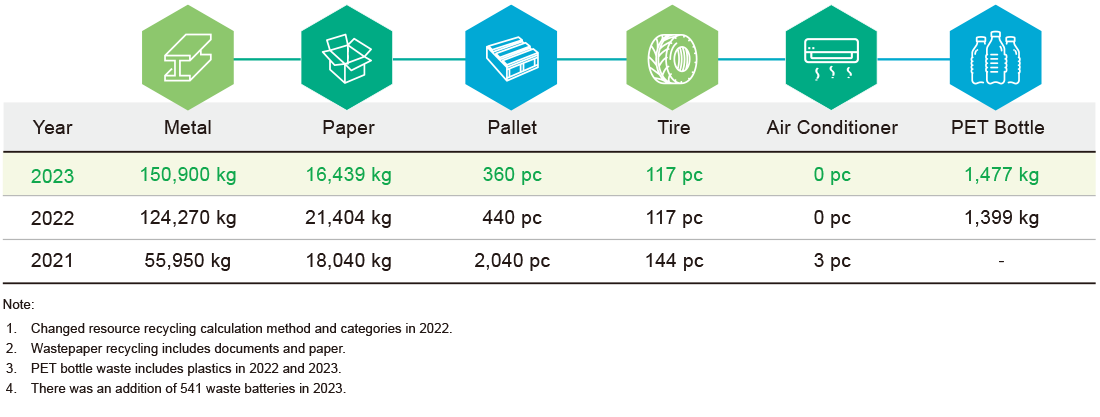

Waste Management

All the waste generated by the OUCC plant is entrusted to qualified waste disposal contractors for removal. No breach of contract by waste disposal contractors in 2022. In addition, recyclable items are entrusted to community charity organizations for recycling after preliminary classification in the plant.

Our Waste Disposal Platform helps accelerate in-plant waste disposal and increase reuse. The goal is to reduce the waste by 5%. We will continue to strengthen the waste control and implement effective management. The Platform helps reduce the waste for the landfill, prevent the employees from wrongfully disposing unfamiliar waste that may jeopardize the safety of the plant.

Environmental Issues Appeal Mechanism

OUCC has stipulated internal and external communication procedures for environment, labor safety and health, and quality management. Any of the environmental opinions or complaints the external stakeholders wish to convey can be sent to the Safety and Health Department, and according to the contents, a specialist from the Central Safety Committee will be appointed to communicate with the external stakeholders, and to investigate or review the issue within the shortest possible time according to its magnitude.

We have a "Stakeholder Contact" and an "Environmental Business Contact (07-6413101#1301)." If an environmental issue arises, OUCC can handle and respond to it immediately. With effective management, there have been no environmental complaints for 10 consecutive years.

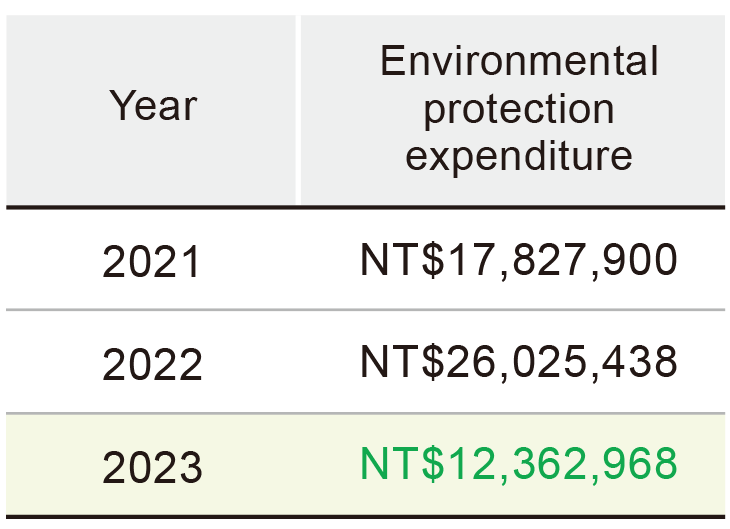

The Environmental Protection Expenditures

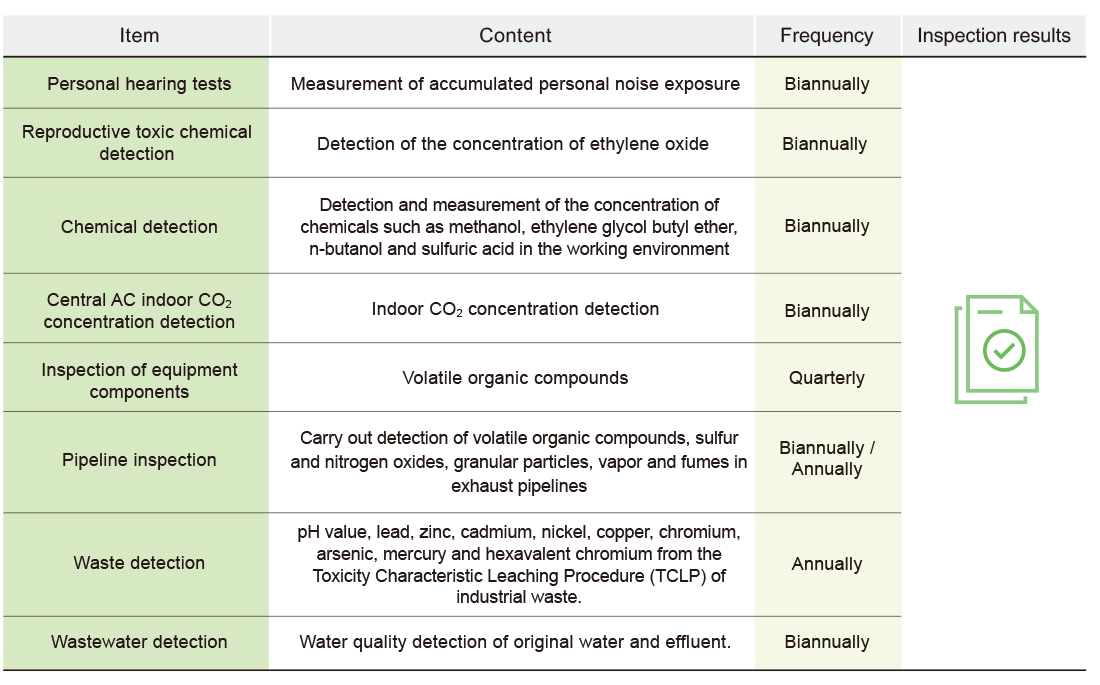

Operational Environmental Tests

We have actively promoted pollution prevention and control systems and improvement plans, such as establishing groundwater monitoring wells and combustible gas monitoring stations, actively recycling carbon dioxide for reuse, establishing waste gas incinerators, and covering various wastewater plants to reduce the environmental impacts from production.

- Improve workplace ventilation and chemical substance volatilization, add ventilation equipment, use protective safety gear, implement safety and health education and training for operators, and execute other related safety operation management.

- An internal/external circulation function switches have been installed in the air-conditioning system of each control room in response to the odor emitted from other plant nearby, intruding through the air-conditioning system and causing discomfort to the staff. With the CO2 concentration detectors added, the air quality is monitored. Also, an activated carbon air cleaner has also been added to the gas control room.

Stakeholders Contactors

- Mr. Chen/Ms. Chang

- E-mail: ESG@oucc.com.tw

SHE Contactors

- Mr. Yeh/Mr. Wu

- E-mail: she@oucc.com.tw