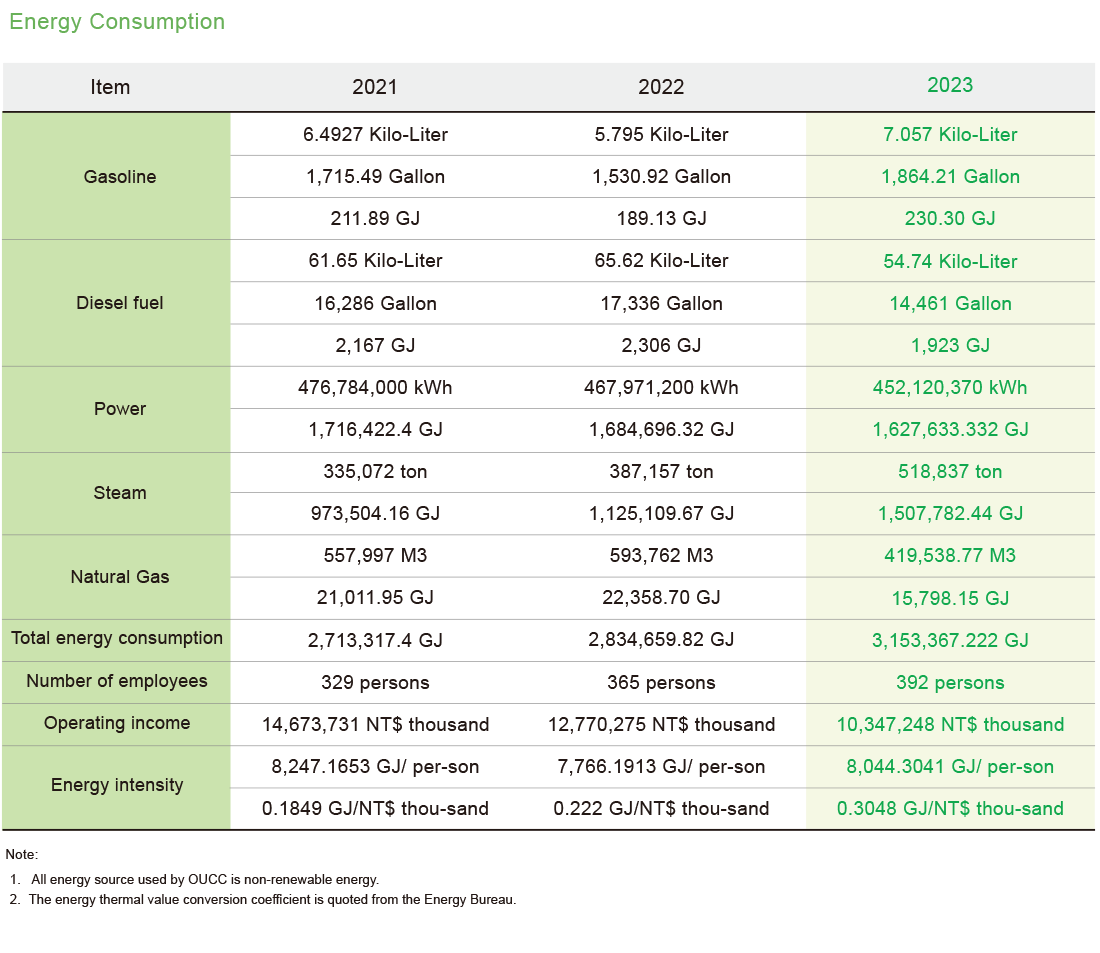

Energy Management Strategy

We at OUCC fully understand that "energy saving" and "intelligent operation" are vital for enterprises that are striving to adapt their operations to a low carbon economy and achieve sustainable operation. To this end, we have introduced the ISO 50001 Energy Management System, improve the cycle through PDCA, keep track of energy usage status, work out appropriate energy management goals, improve energy efficiency in the plant site, and reduce our greenhouse gas emissions.

OUCC Energy Policy

Abide by energy-related regulations; 100% participation in energy and CO2 reduction

Continuously improve energy performance; enhance energy efficiency

Review energy consumption indicators; provide resources to support energy saving

Promote clean production processes; promote energy conservation to reduce costs

Dedicate efforts to achieve objectives and promote green enterprise development

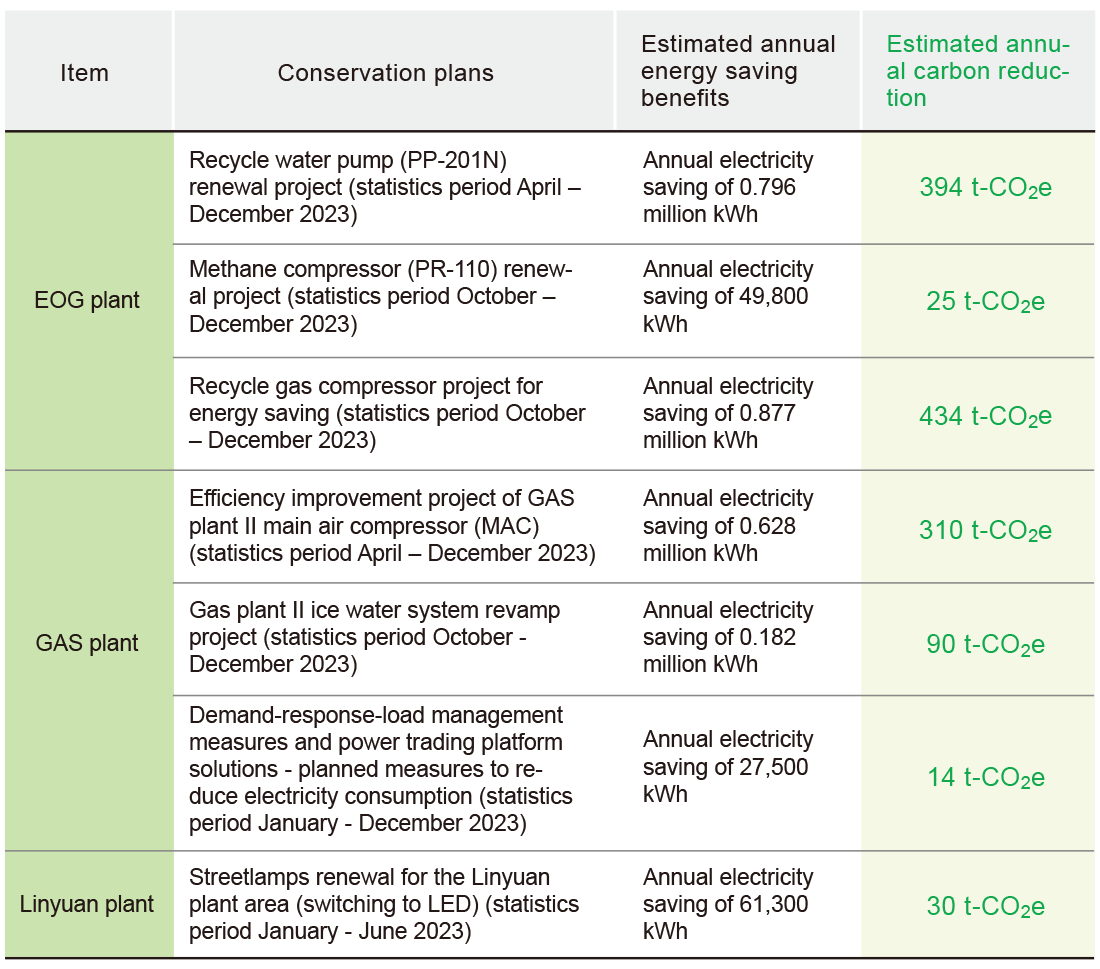

Energy-saving Action Plans

According to the inventory data, 36% of the OUCC greenhouse gas emissions came from electricity. As a response, we set a "power-saving" goal by promoting a series of power-saving measures, looking for suitable fuel- and steam-saving solutions. With effective management, the actual annual power saved was about 2.621million kWh in 2023, with a 0.59% power-saving rate.

Actively Promote Energy Saving at Linyuan

The feasibility of a high-efficiency low-carbon heat and electricity cogeneration system at the Linyuan Plant is being evaluated, in the hope that the electricity and steam will fulfill all the requirements for production. Furthermore, we complied with the terms of large electricity users and completed the 10% contractual capacity of green power procurement in 2023, achieving optimal emission, power saving and carbon reduction objectives.

In terms of technology application, OUCC makes full use of technological advantages to promote clean processes, coupled with a cloud based "plant power monitoring system platform" to monitor energy use by the plant with the structured approach in search of energy-saving opportunities.

In addition, carbon reduction measures in the office area have been promoted, including electronic administrative operations, monitor and control of photocopying over the entire factory, and the promotion of a paperless system for online management, contributing to the reduction of greenhouse gas emission.

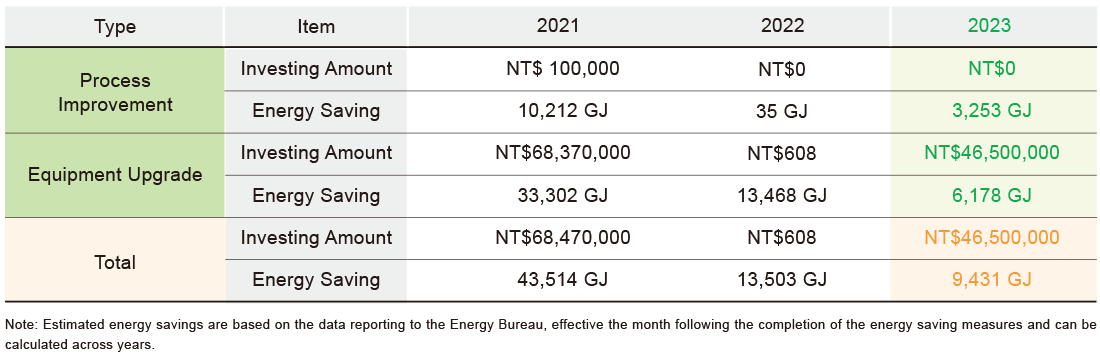

2023 Energy Efficiency Improvement Results

Energy Saving Improvement Results

OUCC’s Linyuan Plant has changed the fuel of the coal fired furnace and the regenerative thermal oxidizer (RTO) systems to clean low-carbon fuel (natural gas). We also installed high-efficiency waste heat recovery technology to reduce fuel consumption and environmental pollution.

Expected Benefits

- Converting the medium-heat heating furnaces and the regenerative thermal oxidizer (RTO-I/RTO-II) incinerators to natural gas burners and deactivating the diesel pumps are estimated to save 8,169 kWh of electricity and reduce diesel consumption by 600 kL annually. The projects were completed by the end of January 2021.

- 2021-2023: The cumulative carbon reduction was about 1,578 t-CO2e。

To beautify the factory surroundings as well as to reduce the long-term problem of flooding, the paving at production processing sites of Linyuan were completed, and underground discharge pipelines were laid and modified at the EOG plant, which included the following:

- Rain and polluted water diversion was established at the leaked wastewater collecting pit of EO loading station / EG / EA filling stations and the recovery system. Modifications were made to the draining chutes to ensure the separation of rain and polluted water.

- The drainage system surrounding the plant was reconstructed and a flood retention pond was built.

Expected Benefits

- The paving at each processing area optimizes the surrounding of the Plant area.

- Both the rain and polluted water were diverted to reduce environmental and industrial safety issues, reducing the occurrence of penalty incidents.

- The drainage system surrounding the plant was reconstructed, which improved the long-term flooding problem, and a flood retention pond was also built to cope with the impact of climate change.

Due to the outdated design of the gas circulating cooler and cooling water tower of EOG plant, there was no way for maintenance personnel to get into the tower to fix an abnormal fan on account of the high temperature resulted from the lack of interior isolation. It would cause the cooling water temperature to rise and require the reaction zone to reduce production.

After reconfirming the overall water distribution and thermal loading of EOG, the circulating water cooler (TT-201N/TT-201) was changed to the #2 cooling tower water supply (where the inside can be isolated for repair).

- The annual electricity saved is about 6 million kWh, which is about NT$13.27 million

- The system can reduce greenhouse gas emissions by approx. 3,218 t-CO2e per year.

- 2019-2023: The cumulative electricity saved is about 30 million kWh, the amount saved is about NT$66.35 million, and the greenhouse gas emission is reduced by about 16,090 t-CO2e.

(1) Photovoltaic system: Installment of a photovoltaic system on the rooftop of the semiconductor CO2 plant at Linyuan was completed by Q1/2023, with capacity of 108.78 kWp and annual average power generation of 153,000 kWh. As renewable energy is self-generated and used, the renewable energy certificate can be obtained.

(2) Co-generation system: Become partial self-sufficiency in terms of electricity, re-adjust the heat and electricity ratio, and plan a high-efficiency and low-carbon co-generation system in response to future energy structure changes.

(3) Medium and long-term plan: Actively evaluate options such as “setup of renewable energy facility (rooftop photovoltaic system),” “purchase green power and RECs,” and “setup of energy storage equipment.” We obtained adequate green power and RECs per year starting December 2023 in accordance with the regulated 10% contracted capacity of green power procurement for the large electricity users.

In order to save energy, the excess steam emitted at Linyuan Plant will be recovered and used to replace the old screw type chiller unit for air conditioning at EOG control room, the laboratory and R&D buildings, with estimated annual electricity savings of 2.07 million kWh, and reduction of 1,040 t-CO2e per year. The cumulative energy savings from 2021 to 2023 amounted to approximately 6.21 million kWh, resulting in a reduction of 3,120 t-CO2e.

Stakeholders Contactors

- Mr. Chen/Ms. Chang

- E-mail: ESG@oucc.com.tw

SHE Contactors

- Mr. Yeh/Mr. Wu

- E-mail: she@oucc.com.tw