Continuous Innovation

A Brighter Future for OUCC

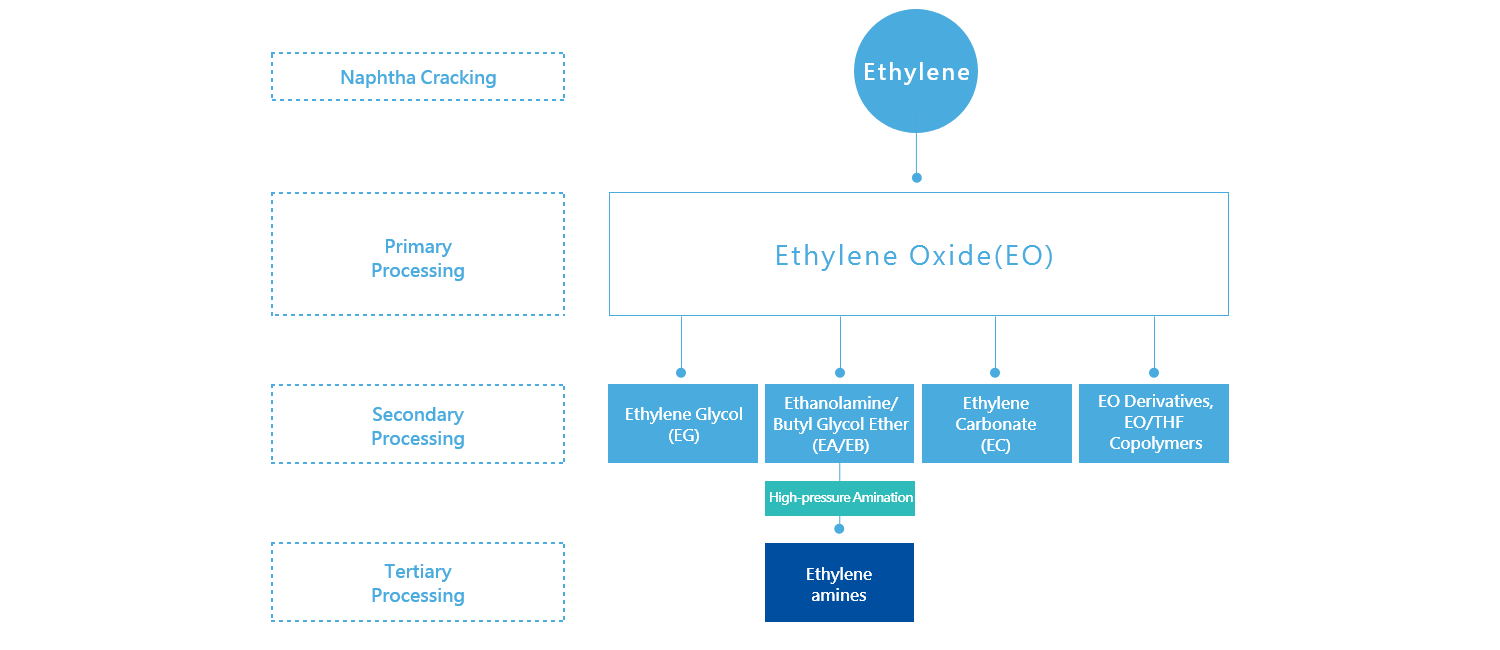

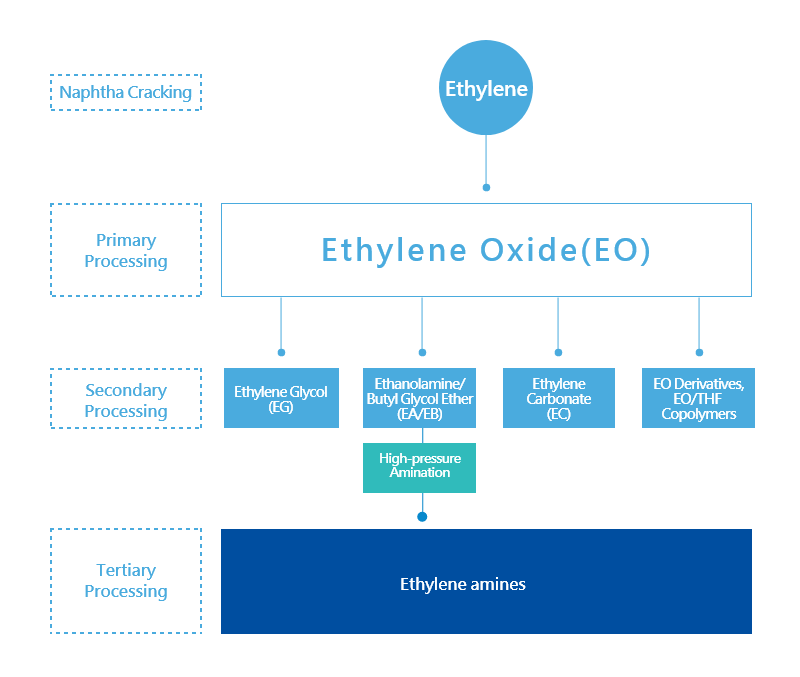

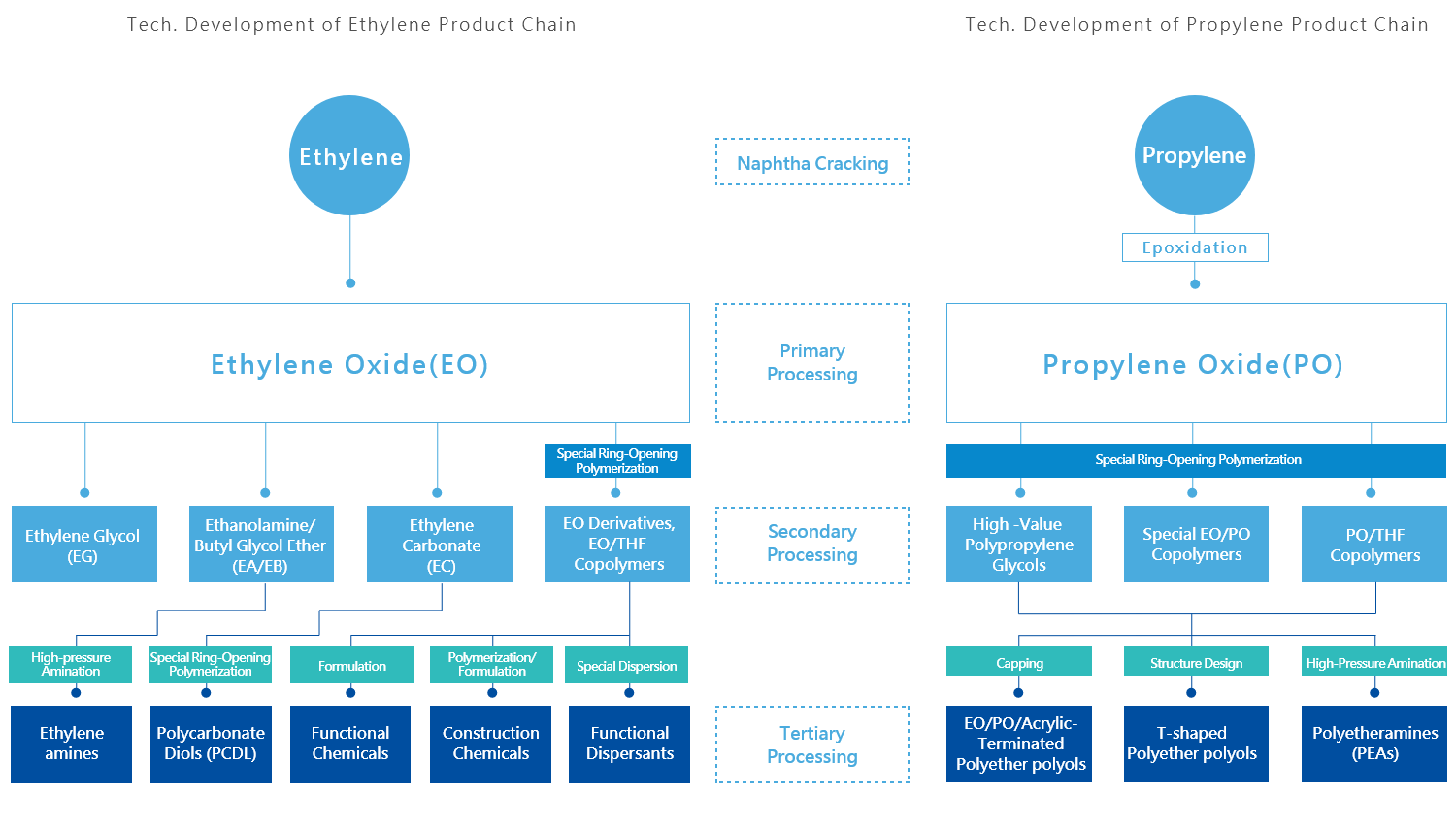

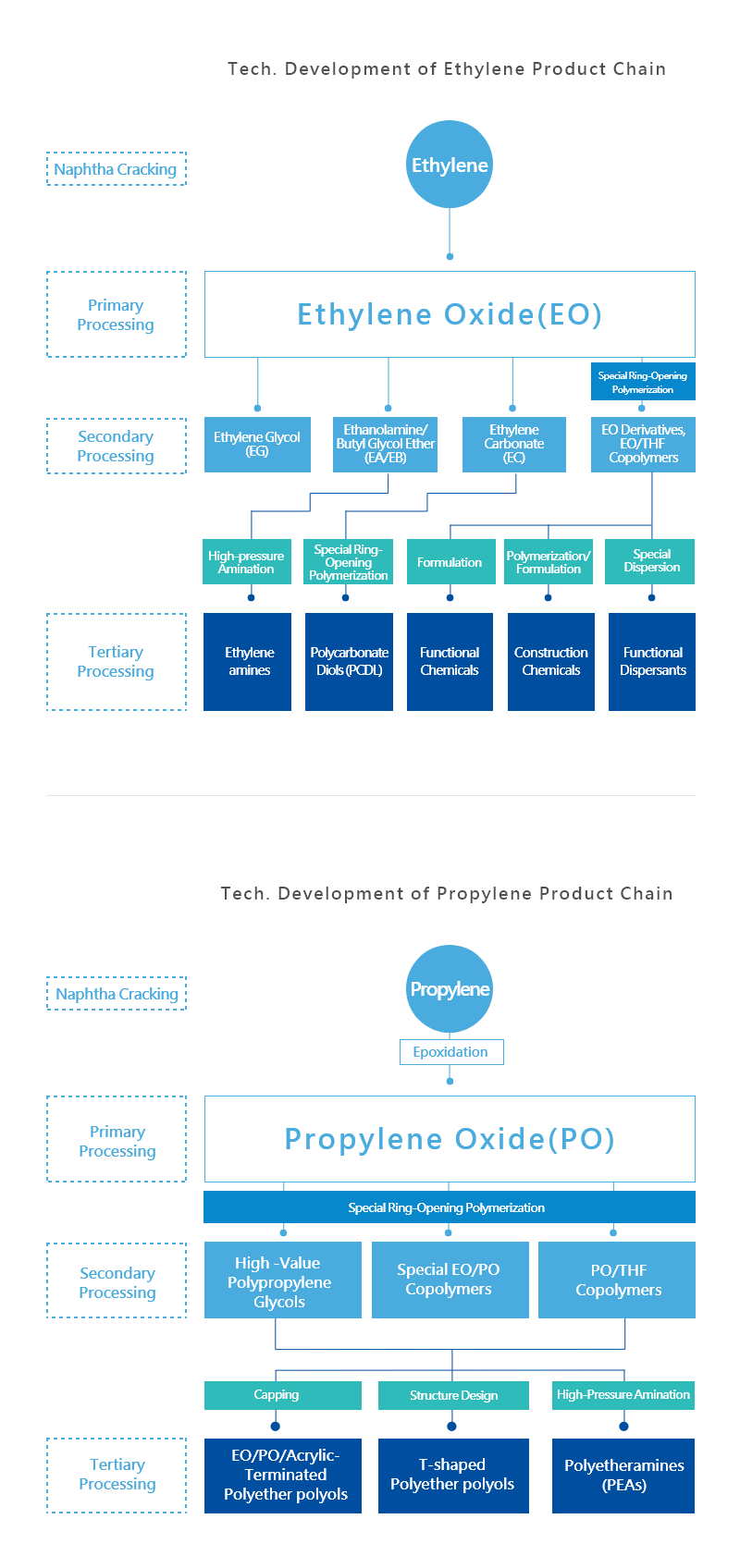

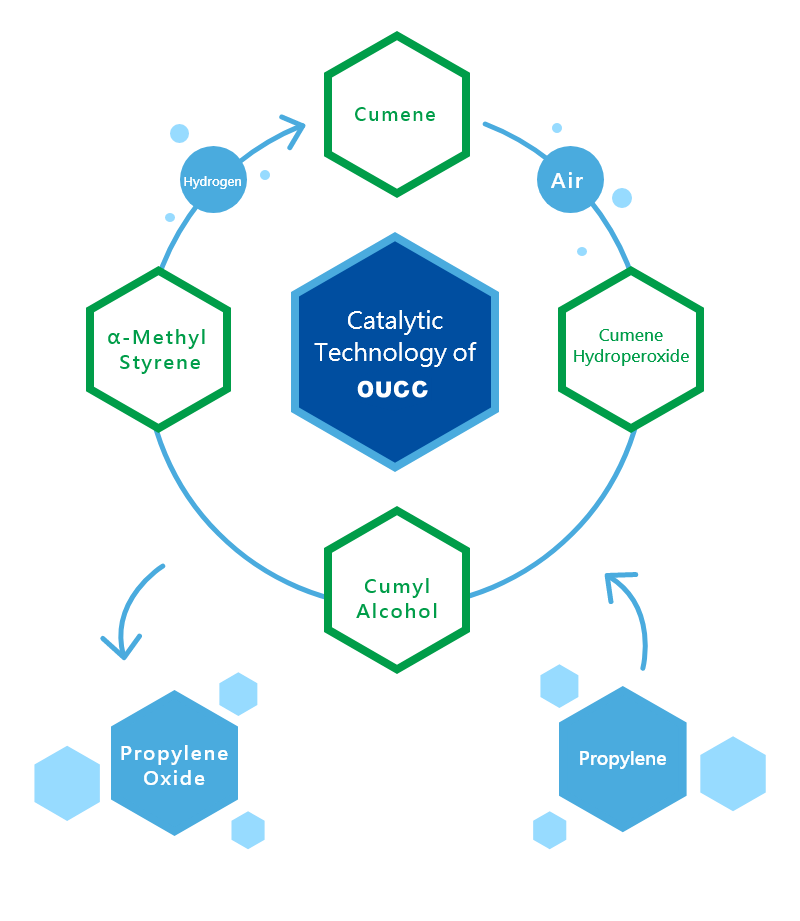

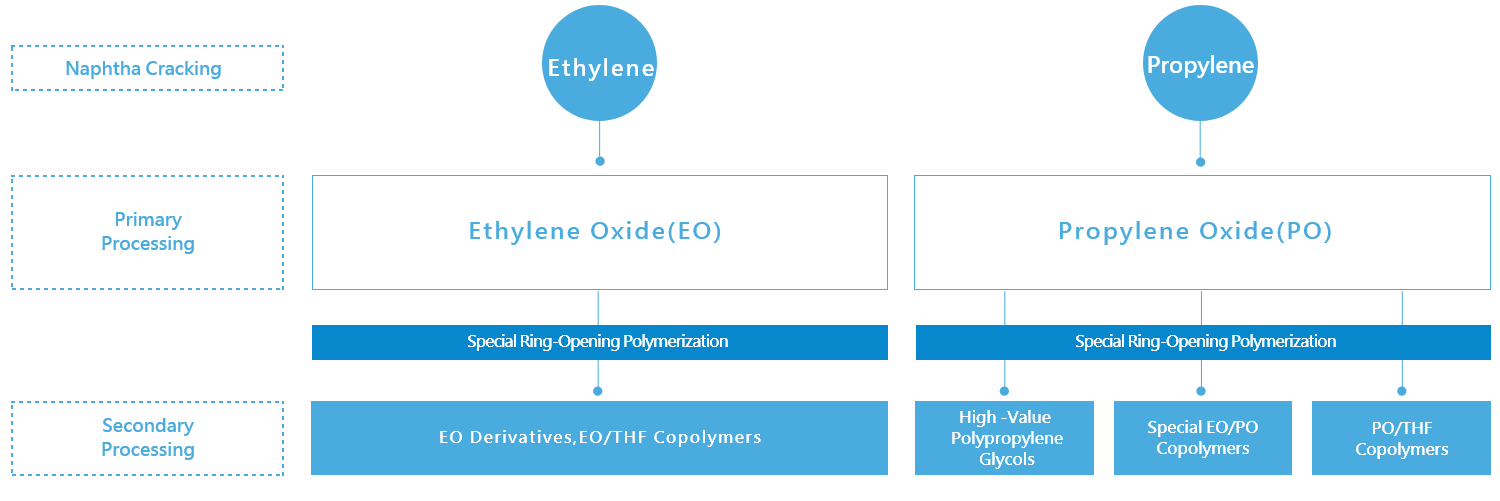

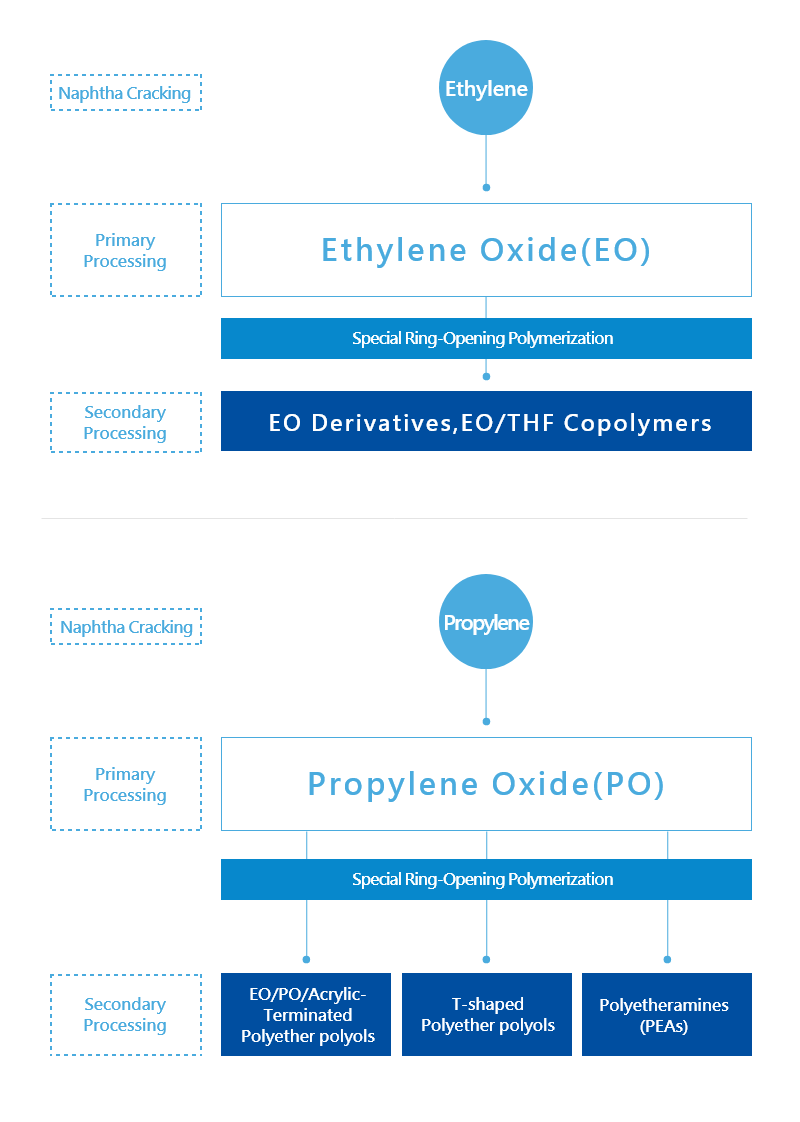

In line with its core spirit of "Innovative R&D", focusing on specialty chemicals, OUCC has teamed up its talents for the development and technical team from material development, process development, quality assurance, engineering design and product development units. The company has established its ethylene and propylene related product chains, using ethylene and propylene as feedstock to go with its own technologies and structural design in epoxidation, special ring-opening polymerization, high-pressure amination, formulation, polymerization, special dispersion, and end-capping for further processing. OUCC will continue to expand the product applications with its extraordinary innovative technology and development capabilities for new products of various domains, to create sustainable new value of chemistry.

Product Area

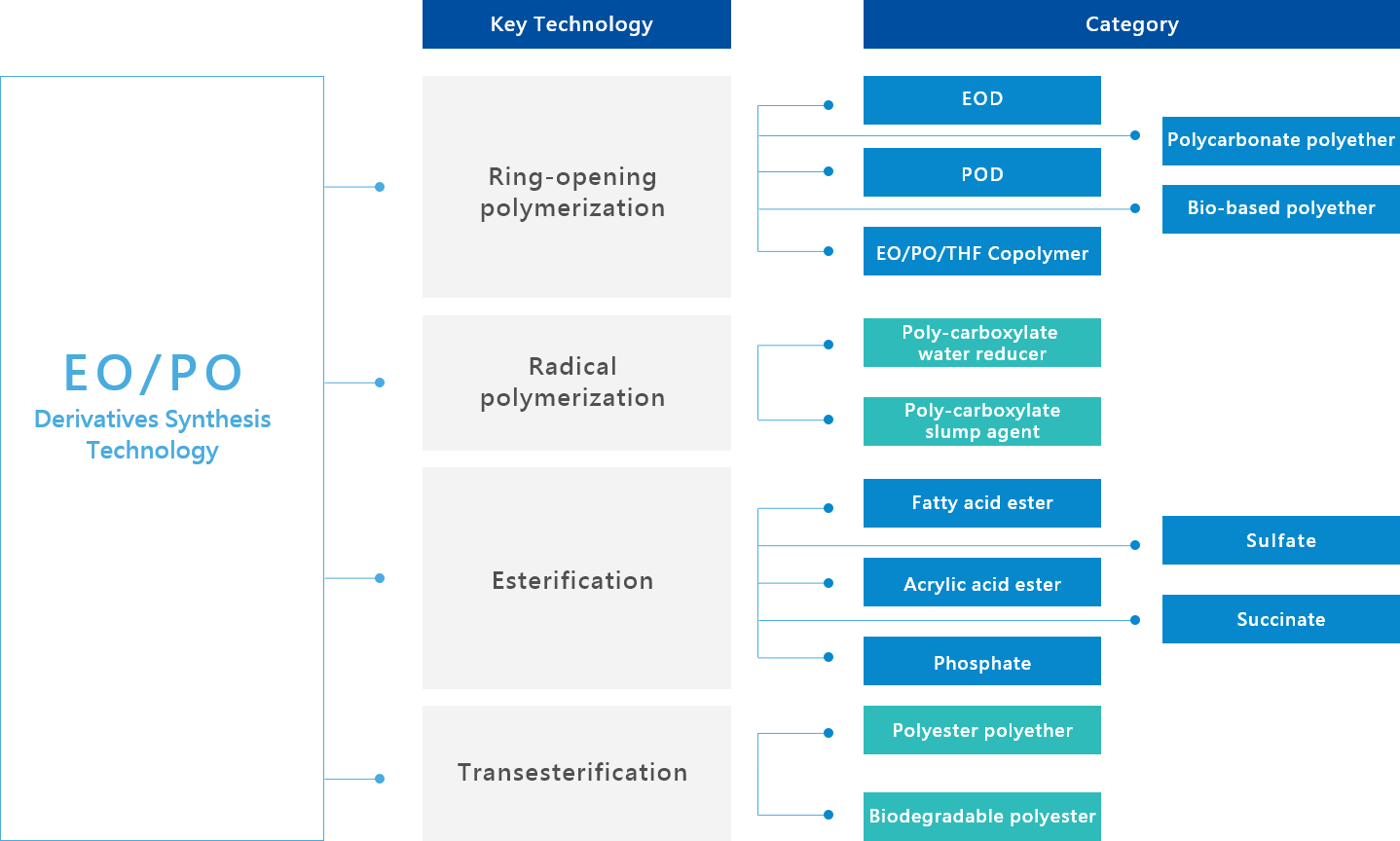

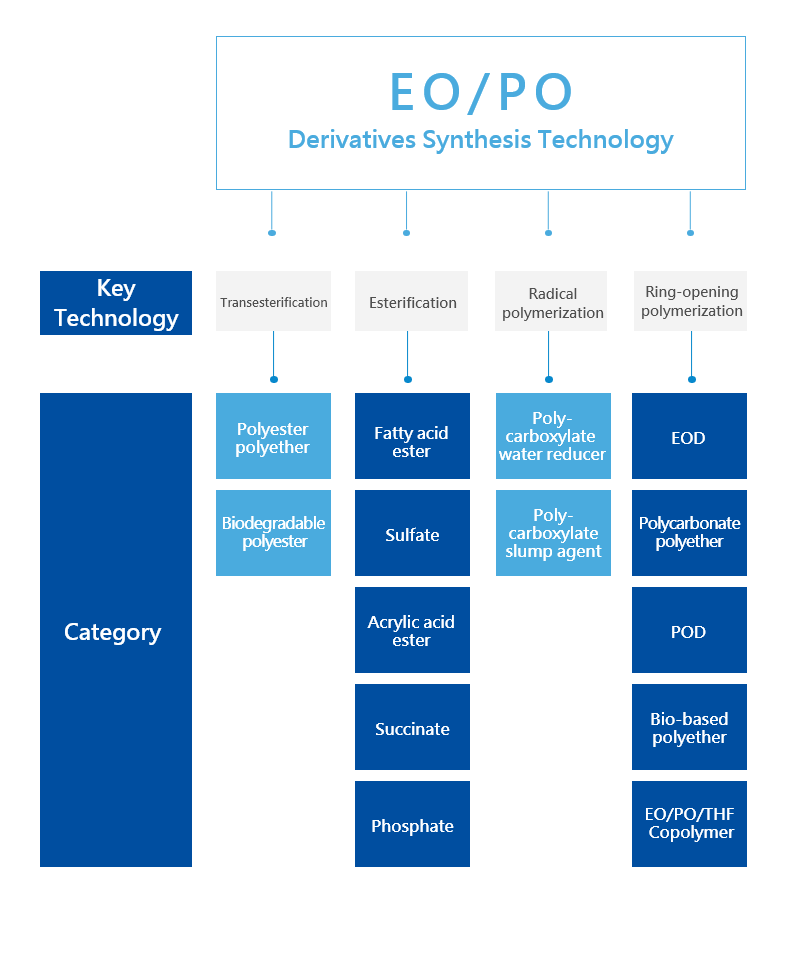

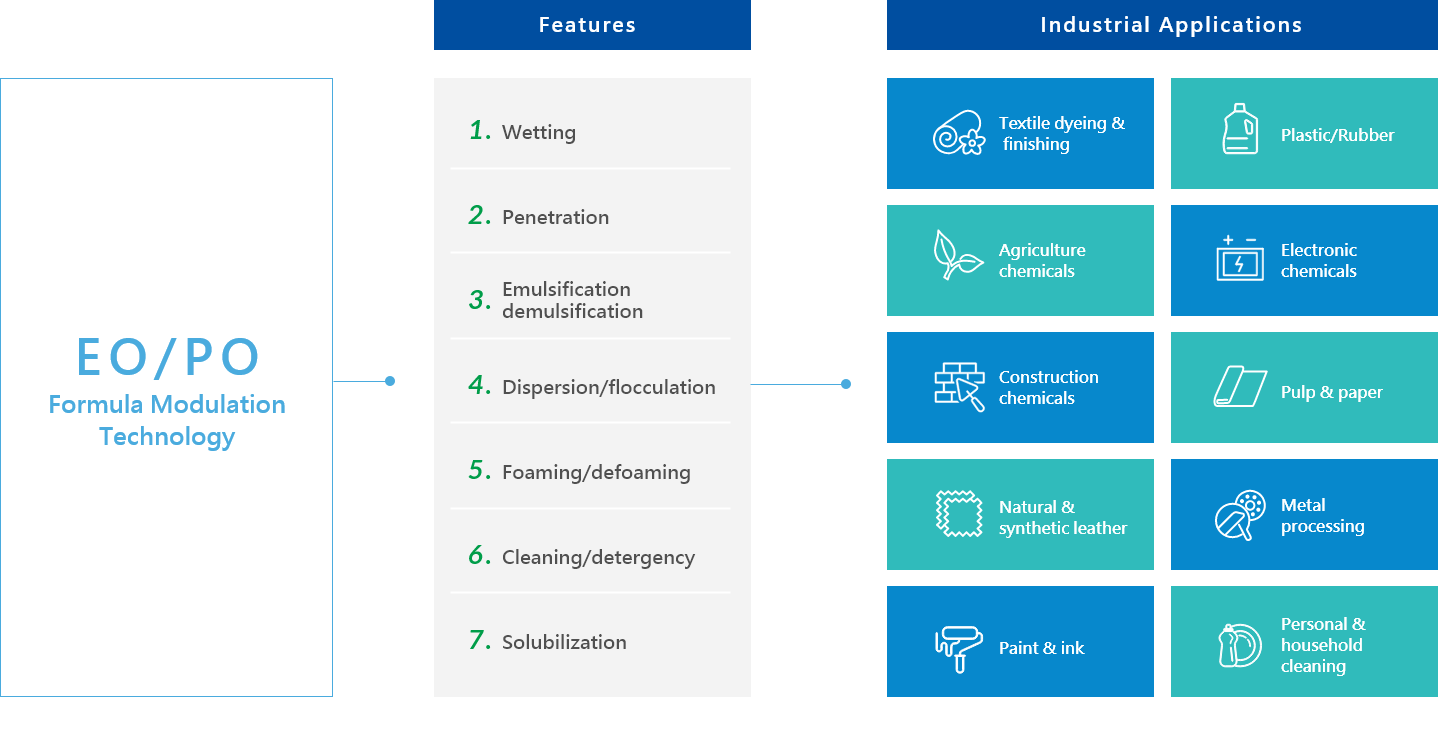

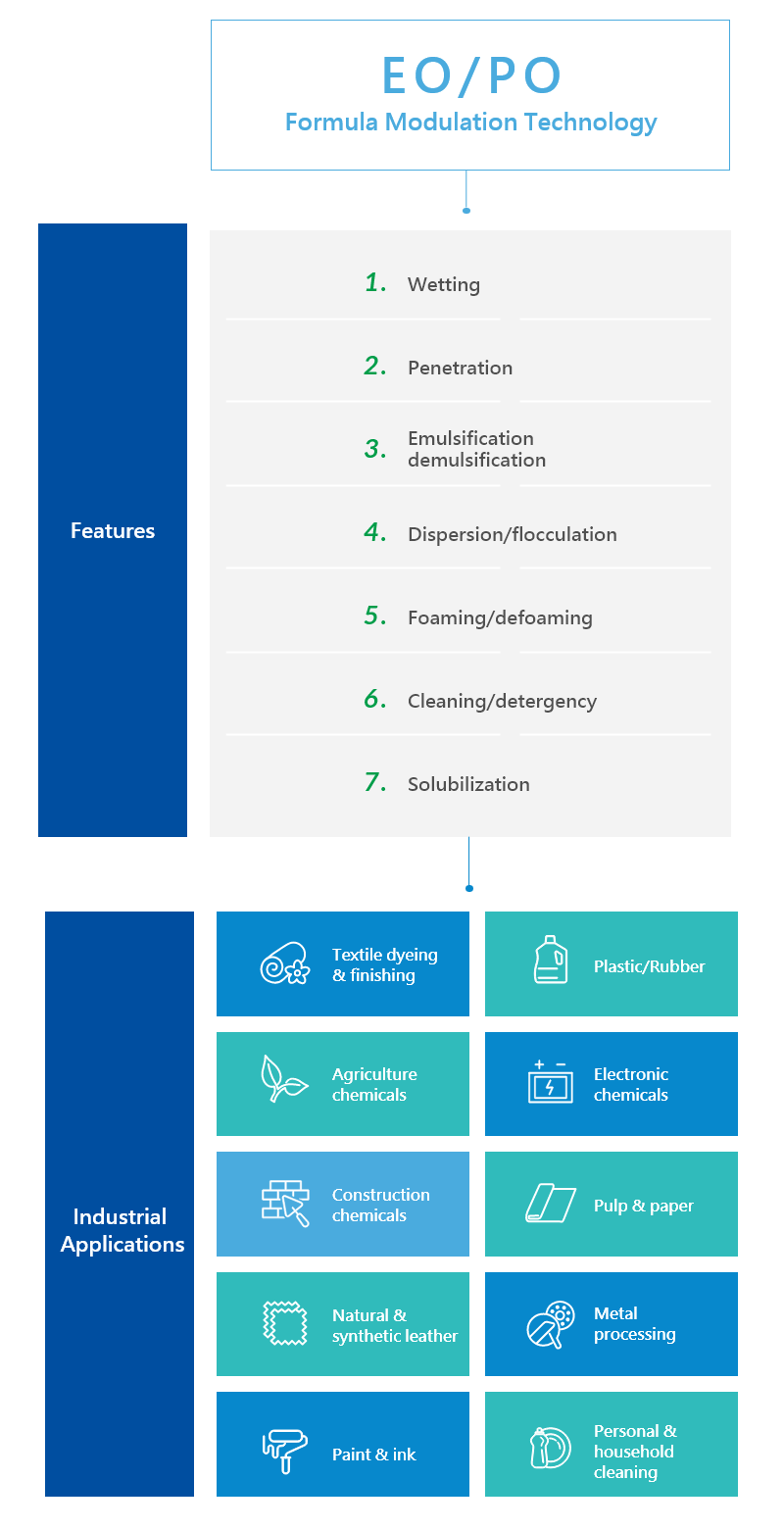

EO/PO Derivatives Synthesis and Formula Modulation Technology

Since the establishment of OUCC, EG has been the prime product, which has the vantage of master control over the development and production of EO derivatives. Given the risks in business cycles of EG and other bulk petrochemical raw materials, OUCC has transformed its core business to Specialty Chemicals development in terms of risk management. In addition, with OUCC’s successful development in catalytic technology for PO synthesis, the PO derivatives development and production have hence been proceeding accordingly. The total of customized high-quality EOD/POD produced thru the incessant development in recent years, has exceeded 50 series and 200 items so far, which product qualities have also been commended by downstream customers. Future marketing shall focus on more customization to meet customers’ requirements based on current foundation.

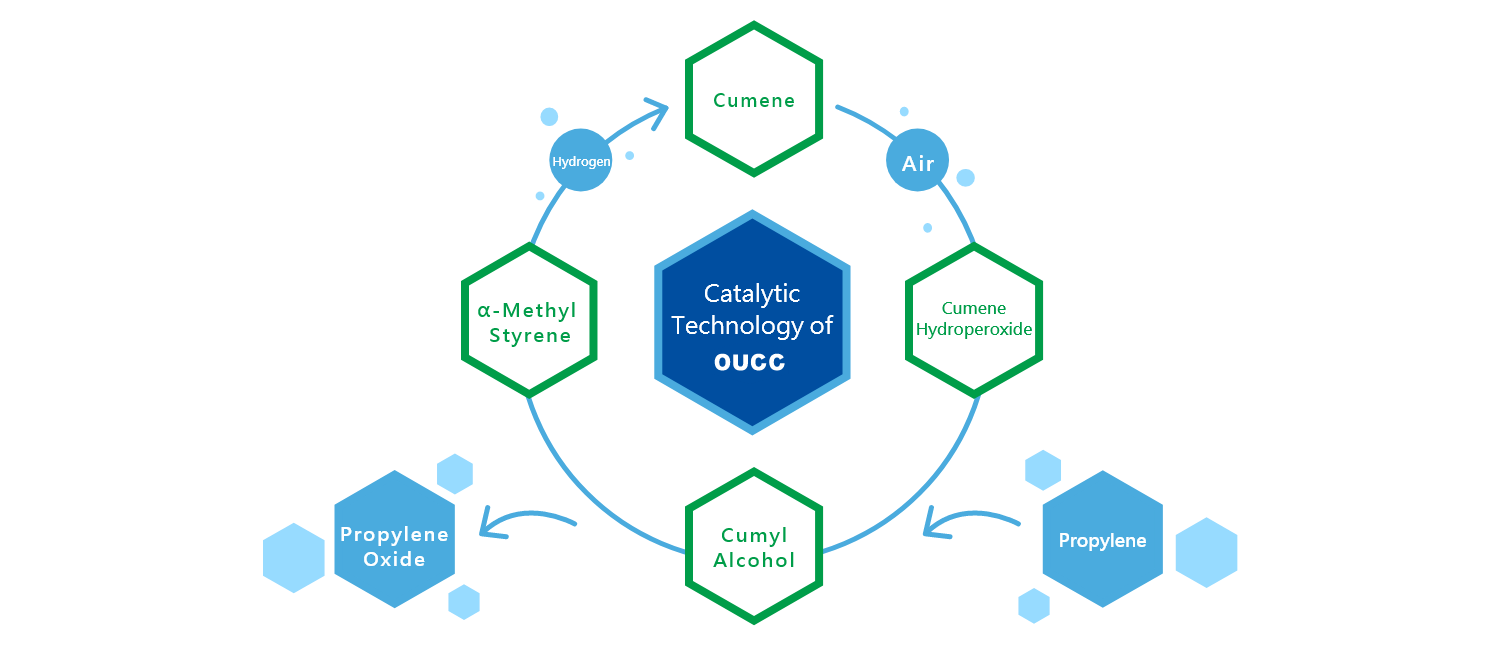

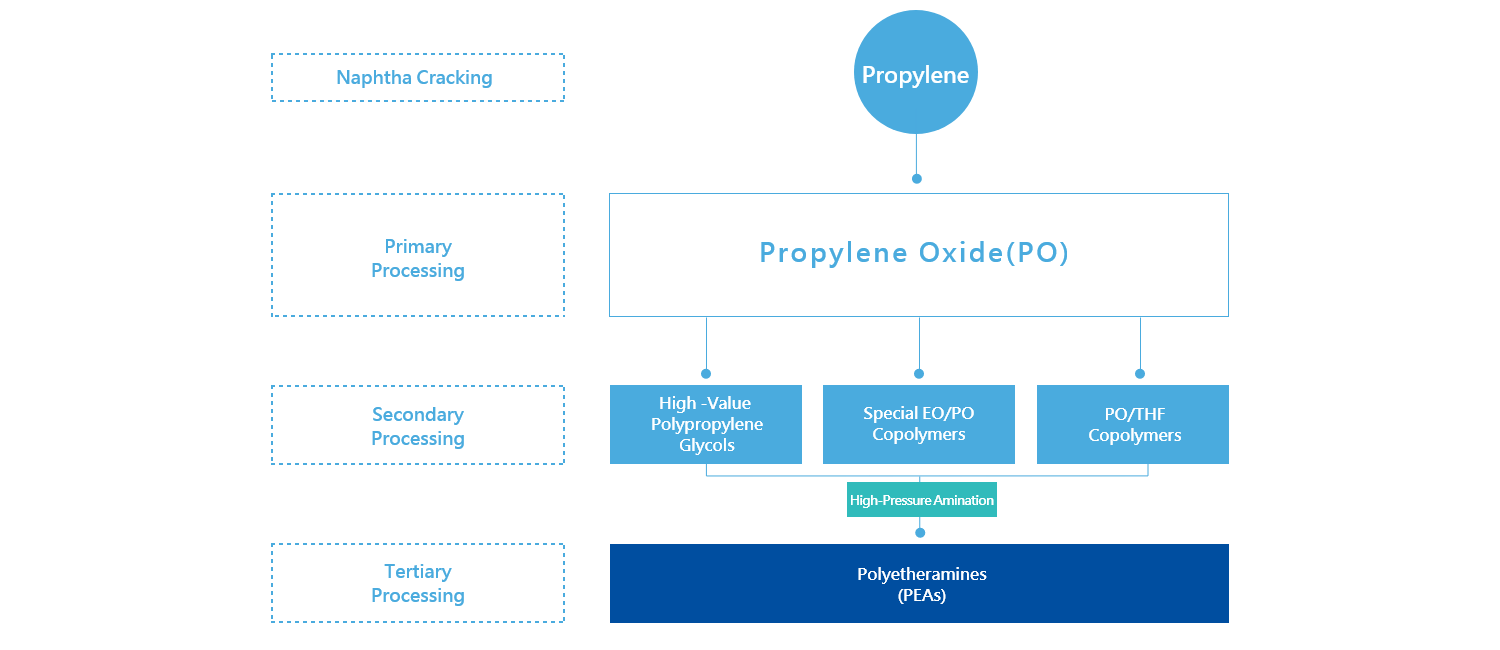

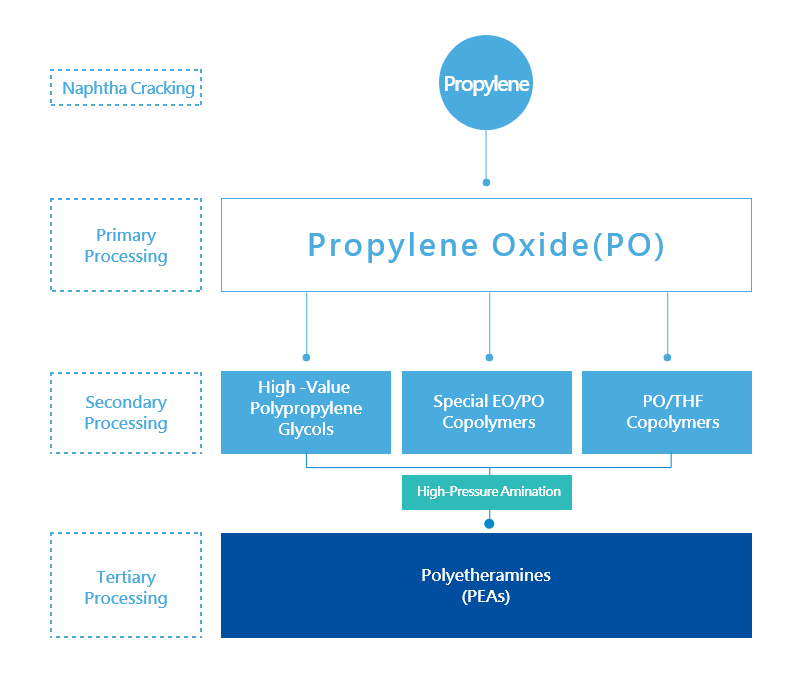

Propylene Epoxidation Technology

Propylene oxide (PO), as the second largest among the three major propylene derivatives, is mainly used to produce propylene glycol, polyether polyol or as a raw material for organic synthesis used in synthetic resins, foams, synthetic glycerin, organic acids, cellulose, flame retardants, plasticizers, which applications extend to furniture, home appliances, automobiles, building insulation materials, coatings and other fields. The volume of downstream derivatives is huge and the applications are getting bounteous.

In order to strengthen the planning of the entire propylene-related product tree, OUCC uses the CHPPO process as the main technology for propylene oxide production. The properties of the CHPPO process are that, in addition to the PO output that can be sold straightly, other raw materials or by-products can be recycled and reused pursuant to the circular economy strategy of the government. The key catalytic technology developed for the CHPPO process by the R&D team has obtained a number of domestic and foreign patents, and implemented to establish the first set of domestic process technology and equipment for the consecutive production of propylene oxide. With the laboratory PO circular production test completed, the establishment of a pilot plant shall proceed subsequently.

Correlation diagram

Special Ring-Opening Copolymerization Technology

In recent years, a number of special ring-opening technologies in line with OUCC’s strategy in customization development have been established. Among which is the synthesized polyether polyol of special spec., which not only have improved remarkably the product quality, but also have adjusted the polymerization rate to enhance the HMW uniformity of copolymer, since the establishment of the company’s mass production capabilities of such series in 2019.

With each series molecular weight reached over 20,000, the physical or chemical properties of the special spec. polyether polyol can be adjusted in accordance with the specific needs. Current special spec. polyether polyols can be applied to various polyurethane (PU) resins such as surfactants, resin modifiers, raw materials for daily chemicals, adhesives, sealants, elastomers, rigid and soft foams to enhance the quality and physical properties of terminal products, ensuring the best product quality of OUCC.

High-Pressure Amination Technology of Polyether polyols

Polyetheramine, as an amine compound, possesses properties such as high reactivity, high flexibility, high toughness, low viscosity, and low product hue, which can adjust and optimize the physical properties of resin, can be applied to the spheres of epoxy resin, polyurethane (PU), polyamide fiber and other resin industries, as well as to coatings, construction, and daily necessities.

Based on the high-precision R&D and production technology, OUCC has successfully developed high-pressure amination technology, and established the first set of domestic process technology and equipment for the production of polyetheramine derivatives (PEAs), with self-produced polyether polyols as feedstock. Presently, laboratory production and application tests have completed, mass production is expected by 2021.

High-Pressure Amination Technology of ethanolamines

As ethylenediamine (EDA), diethylenetriamine (DETA), aminoethylethanolamine (AEEA), piperazine (PIP) and other ethylenediamine-related products can be widely applied to resin additives, electroplating, pharmaceutical, agriculture, textile, paper, solvent and other industries, OUCC has used the self-produced ethanolamine as feedstock, along with the independently developed high-pressure amination and purification separation technologies to successfully establish its first set of domestic consecutive production technology for the production of ethylenediamine and its derivatives, which include ethylenediamine (EDA), diethylenetriamine (DETA), aminoethylethanolamine (AEEA), piperazine (PIP) and other ethylenediamine-related products. Presently, laboratory production and application tests have completed, mass production is expected by 2021.