Safe and Healthy Workplace

The OUCC has joined the Taiwan Responsible Care Association (TRCA) to promote responsible care and taken up six standard management guidelines to ensure plant safety, including process safety, emergency response safety, distribution safety, contractor safety, waste and reduction management, and product safety management.

- The senior supervisors of the factory have formulated a 5S safety team to carry out regular weekly patrol inspections according to the areas, keep track of any equipment gaps or environmental hazards, and offer suggestions for improving the inspected unit so that anomalies can be identified instantly.

- Promote and implement "TPM total production management/maintenance inspection" to strengthen the safety cultivation.

- The GRI 403 described in this chapter only applies to the Linyuan plant, with

the Taipei headquarters excluded.

Record of Awards

- Received the “Self-Response to Global Energy Conservation Activities” certificate of appreciation from the Environmental Protection Bureau.

- Assisted in the “Dafa Industrial Park factory pollution prevention exchange workshop”, and received a certificate of appreciation from Dafa Industrial Park Service Center, Industrial Development Bureau of the Ministry of Economic Affairs.

- Assisted the Ministry of Education and Fooyin University in the implementation of University Social Responsibility (USR) project - “Dafa Industrial Park factory pollution prevention exchange workshop,” and received a certificate of appreciation.

- Received an outstanding performance award from the Taiwan Responsible Care Association (TRCA) in the participation of emergency response practice drills.

- Recognized by Industrial Development Bureau of the Ministry of Economic Affairs as the outstanding performance company for 2020 self-reduction in greenhouse gas emissions.

- Received a certificate of appreciation from the Health Department of Kaohsiung City Government for proactively advocating workplace cancer prevention.

- Received an award plaque from Taiwan Responsible Care Association (TRCA) for holding a conjoined on-site drill for toxic substance (ethylene oxide) incident.

- Received an award plaque from Taiwan Responsible Care Association (TRCA) for participating in the Responsible Care Seminar.

- Received award plaques for participating in National Toxic Substance Accident Mock-up exercise from Environmental Protection Administration of Executive Yuan and Kaohsiung City Mayor.

- Received an award plaque from CPC Corporation, Taiwan for participating in Critical Infrastructure Protection Evaluation and Exercise.

- Received award plaque from IDB, MOEA for outstanding performance in reducing greenhouse gas emissions.

- Received a certificate of appreciation for participating in the project of Strengthening Industrial Public Safety Management organized by the Industrial Safety and Health Association of the R.O.C.

- Due to the severe COVID-19 status in 2022, the activity participation rate was reduced in compliance with the company’s epidemic prevention policy.

- Received a certificate of appreciation from Ministry of Environment for participating in the case sharing of the 2023 National Environmental Incidents Case Study Seminar & Award Ceremony for Excellent Operation and Management Joint Defense Organization.

- Received a certificate of appreciation from Health Dept. of Kaohsiung City Government for participating in the “2023 Kaohsiung City Workplace Employee Health Service Promotion Plan” and rewarded as Outstanding Group for the promotion of workplace cancer prevention and treatment.

- Received a certificate of appreciation from Fire Dept. of Kaohsiung City Government for donating fire alarms.

- Awarded the Health Promotion Label by the Health Promotion Administration of the Ministry of Health and Welfare for promoting workplace tobacco hazard prevention and health improvement.

- On 10 July 2023, Simon Chen, Senior Manager and W. L. Yeh, Senior Specialist of SHE Dept., participated in the Industrial Safety Week observation activities of CPC Petrochemical Division for ideal experiences learning.

- On 12 December 2023, Y. S. Chang, Vice President, led relevant supervisors to participate in the general inspection & high-level promotion symposium of factories to strengthen factory risk management under the jurisdiction of the Industrial Park of the Ministry of Economic Affairs.

Comprehensive Occupational Safety and Health Management

According to national laws and regulations, OUCC has established and obtained ISO 45001:2018 Occupational Safety and Health Management System certification. In addition to completing the hazard operation (HazOp) assessment before the plant construction, we have also formulated the "Procedure for the Management of Change (MOC)” for any changes involving process equipment, process chemicals, process technology, safety facilities, operating procedures, etc., to ensure the safety management of each operation after the change.

Scope of application of the OUCC Occupational Health and Safety Management System:

- Include approx. 493 employees (345 employees + 148 contractors) in the Kaohsiung Linyuan plant, locating at No. 3, Gongye 3rd Rd, Linyuan District, Kaohsiung City, with 100% coverage rate.

- Operation activities, products or services of controllable, influential employees of all units at the OUCC Linyuan plant and all contractors who enter the facility’s perimeter.

- The number of people covered by the internal & external management system audit: 493 people, covering 100% of the employees.

Solid Occupational Safety and Health System

OUCC has established an Occupational Safety and Health Committee with the chief plant Director as the convener. A total of 14 representatives participated, including 7 labor representatives, accounting for 50% of the committee.

The committee holds the meeting quarterly. Its main responsibility is to review and coordinate the occupational safety and health issues submitted by employees. After the records are completed, the results shall be announced to all employees. The Occupational Safety and Health Committee reviews the issues related to occupational safety and health inside and outside the factory pursuant to the items required by laws and regulations.

Diversified Health Management Project

OUCC cares for employees' personal health and provides them with comprehensive health resources, a comprehensive assessment mechanism and a health management program, which can also be extended to their families, include health checkups, health consultations, health education, diversified health seminars, employee assistance programs, as well as programs for the prevention of human-induced hazards. These services help employees to manage their own health, to create a friendly and healthy work environment.

OUCC has been attentive to the issue of employee overwork. OUCC Linyuan plant has established, implemented and promoted "Prevention of Disease Caused by Abnormal Workload Procedures," and take safety and health preventive measures related to overwork to ensure the physical and mental health of employees, to further reduce the employee’s long-term work pressure and job fatigue cumulation due to shift rotation, night shift work and long working hours, which affect the physical capability and cause the risk of cardiovascular disease. In 2023, there was no occurrence of employee overwork, saved for some with high health risks and under health control after consulted with the plant physician.

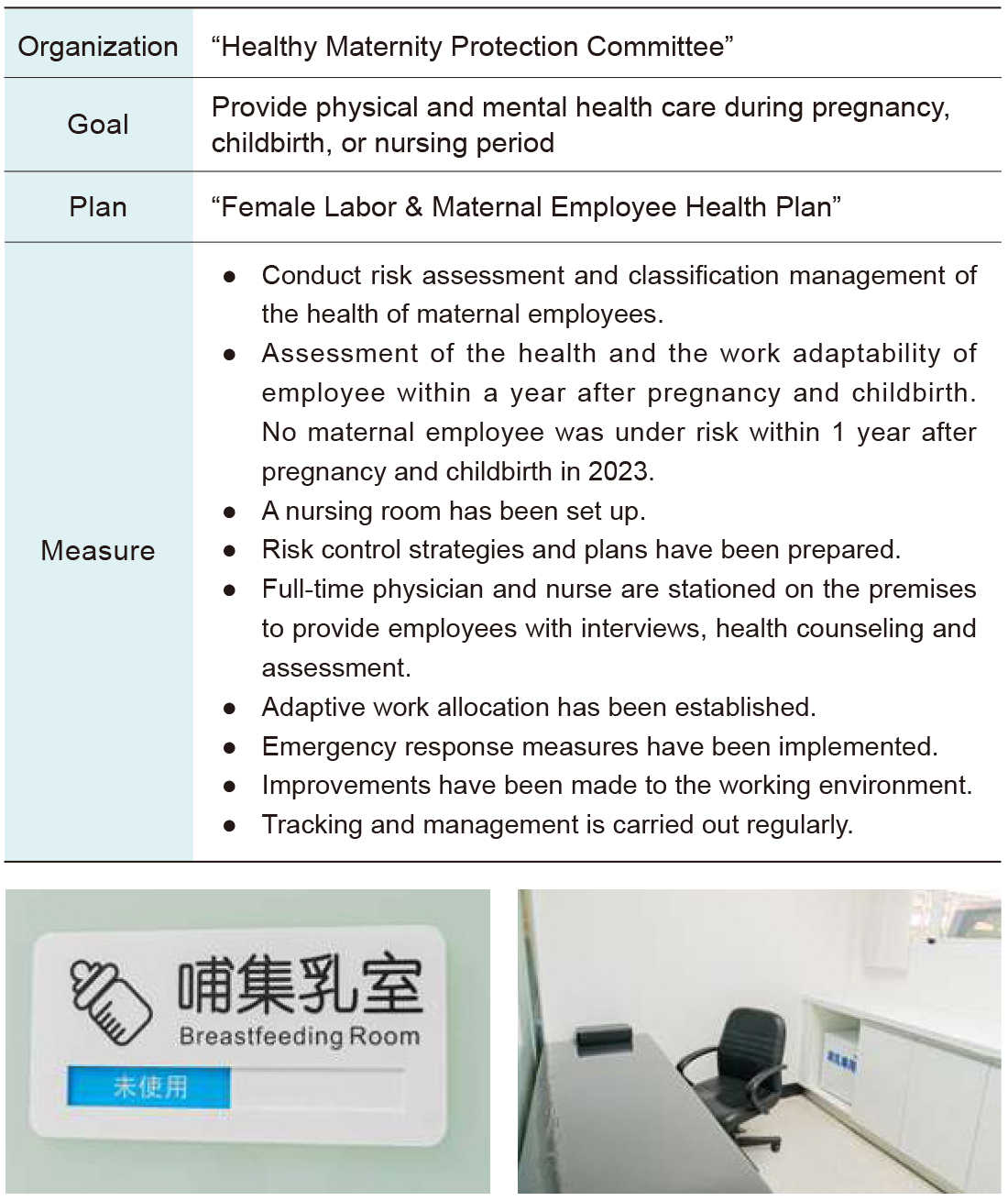

A "Healthy Maternity Protection Committee" has been established by Human Resources Department, the SHE Department, plant nurse, and supervisor of the workplace maternity unit to study maternal health hazard control and work adaptability adjustment practices. Risk levels are classified and adjusted in accordance with health risk assessment to ensure the work nature is in line with a proper level of health care for female employees.

Occupational Safety and Health Management System

OUCC follows the safety and health implementation project, establishes a people-oriented safety culture, and anticipates to implement comprehensive safety management and control.

Stakeholders Contactors

- Mr. Chen/Ms. Chang

- E-mail: ESG@oucc.com.tw

SHE Contactors

- Mr. Yeh/Mr. Wu

- E-mail: she@oucc.com.tw