Manufacturing Process of Zero Damage

OUCC has carried out manufacturing process hazard and operability (HazOp) analysis on hazardous processes associated with higher risks. A hazard prevention model and the risk management process have been constructed to reduce the probability of industrial accidents.

We have introduced the Layers of Protection Analysis (LOPA) technology into the newly established EOD plant since 2010 to effectively strengthen the safety protection layer and achieve the expected risk management effects.

- LOPA analyses of the existing processes were 100% completed.

- In 2023, two HazOp & LOPA risk identifications in the workplace of GAS plant, as a 5-year regular review, and the ethylene oxide process area modification were implemented to improve safety.

- Each unit carried out general hazard identification using the risk ratings chart; a total of 10 improvement cases were tracked in 2023.

Risk Hazard Analysis

Process risk holds the key to plant safety. In 2023, we conducted HazOp & LOPA risk identifications in the workplace of GAS plant, as a 5-year regular review, and the ethylene oxide process area modification, with 6 improvement recommendations, which were all completed.

Production Process Disaster Prevention Measures

Safety Prevention Mechanism

① Occupational Safety and Health Management Standard Operation Procedures (SOP)

- The environmental health and safety policy as set down in the "Environmental and Occupational Health and Safety Management Handbook" has been revised in response to the resolve of top management, request of the FE Group, and anticipation of stakeholders in view of the environmental safety and health.

- "Occupational Health and Safety Risks and Opportunities Management Guidelines" effectively identify the risks and opportunities of the occupational health and safety management system. We continue to enhance performance through active improvements to the occupational safety and health management system.

- The "Safety Manual for Work in Confined Spaces" lists safety management for all work operations in confined spaces to ensure personnel safety.

- "Environmental Safety Certification Requirements for All Levels" have to be followed by the supervisors of all units and apply to all levels of staff in need of certification.

- "Safety Management of High-Pressure Water Column (Water Blade) Operations" requires that all the necessary tasks be taken in strict compliance with regulations to ensure and maintain the safety of personnel.

② Safety Data Sheet and Hazard Labeling of Chemical Substances

All raw materials and products used in the plant have associated material Safety Data Sheets (SDS) which are kept on-site and in the offices of each unit. They are also accessible on the Internet platform for employees’ checking at all times. This ensures that all the proper actions to be adopted to secure the safe handling of the material and the safety of personnel and the plant.

③ Sobriety Testing Before Entry

The "Work Rules" stipulate a sobriety test for employees entering the plant: For employees and contractors, alcohol testing is conducted at the factory as appropriate to deter and ensure the effect of alcohol-free entry into the factory. Employees or contractors who fail the sobriety test are denied entry. An employee who violates the rules will be dealt with according to the Work Rules. Contractors in violation will be penalized under the Contractor Operation Safety Commitment.

④ Safety and Health Education Training

- Continue to promote "safety, health, and environmental protection education and training." In 2023, a total of 4 courses were held with 309 participants and a total of 32 training hours. To ensure that employees can apply what they have learned, they can instantly submit or raise their questions, if any, during the course, to conduct effective two-way communication.

- A test of “Procedures for Work Safety Management” was held at Q4/2023 to enhance employees’ safety awareness. The participants totaled 170, with qualification ratio of 69%. Rest of the unqualified employees were coached and retested with 100% qualification rate.

- Notices of ear protection gear application are displayed at all the entrances to the plant with noise pollutant.

- Personal hearing tests are carried out every six months.

- Plant personnel must wear earplugs or earmuffs before entering noise polluted spaces.

- Every employee is arranged for an annual precision hearing test. No employees experienced hearing disorders in 2023.

- A full-time physician and a nurse are stationed in the plant and provide employees with health checkups and healthcare.

Non-disaster Man-Hours

OUCC promotes the following mechanisms to enhance the safety awareness of all our workers and contractors, to achieve the goal of accident-free man-hours:

- 5S patrol inspections are implemented by supervisory personnel every week. The safety branch will conduct a safety audit every month with improvement tracking carried out.

- Combine occupational health and safety with personnel key performance indicator (KPI), which links with employees’ performance bonuses. And we encourage all personnel to report false alarm incidents.

- The Plant supervisors participate regular safety meetings to discuss, communicate, share experiences and coordinate with each other on safety and health issues.

- An OUCC Safety and Health Line Group has been created and the plant’s supervisors and contractors are requested to join the group in order to reflect, share and communicate ideas and opinions.

- OUCC's cumulative safety man-hours in 2023:637,016 million hours (mid - and long-term goal: 2 million safety man-hours)

- OUCC contractors' cumulative safety man-hours in 2023: 1,698,442 million hours (mid - and long-term goal: 2.5 million safety man-hours)

Improving Workplace Safety by Listening to Employees

- Through regular meetings of the Occupational Safety & Health Committee and the Contractors, we discuss and develop safety improvement mechanisms to effectively reduce occupational safety risks. To ensure the safety of employees in the plant, we review and improve the safety and health items proposed by employees through the "Plant Safety and Health Meeting" held routinely.

- To discover unsafe environment, equipment, facilities and behaviors inconsistent with safety and health in the workplace, we have established the G0300-WI-096 incentive mechanism for False Alarm Incidents and Safety Suggestions Proposals, which encourages colleagues and contractors to proactively propose false alarm incidents and safety suggestions with potential hazards for prevention and correction, and rewards are given to the proposers.

The safety recommendations proposed in 2023 include the following: ![Zero Damage in Manufacturing Process Zero Damage in Manufacturing Process]()

Note:

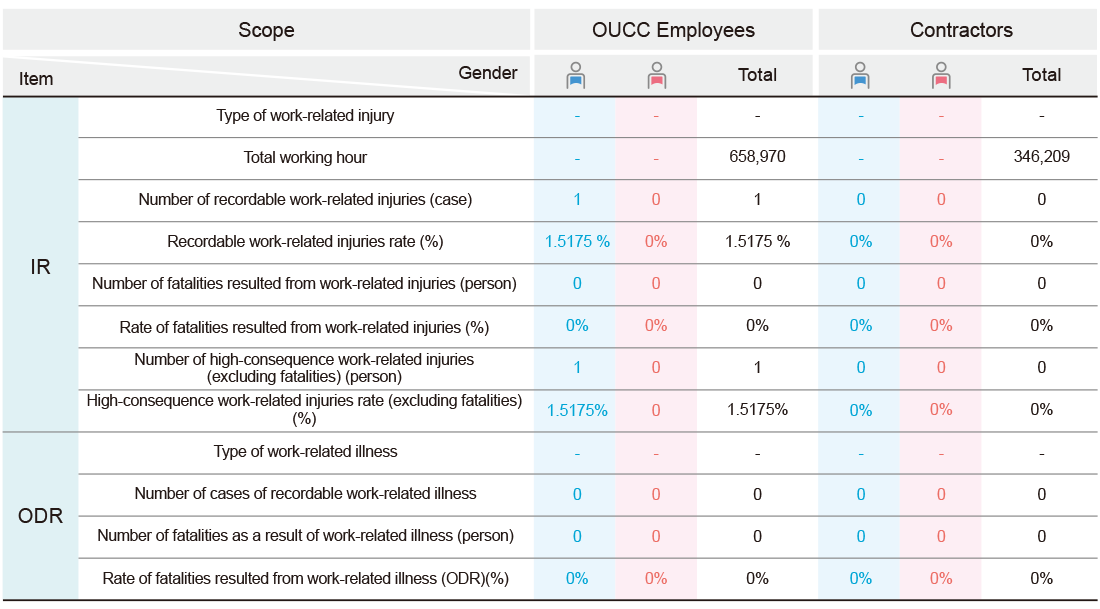

1. Rate of fatalities resulted from work-related injury = (Number of fatalities resulted from work-related injury / total work hours) x 1,000,000.

2. Rate of high-consequence work-related injuries = (Number of high-consequence work-related injuries / total work hours) x 1,000,000.

3. Rate of recordable work-related injuries = (Number of recordable work-related injuries / total work hours) x 1,000,000.

4. Total work hours of contractor / employees: total work hours of contractor, individual or organization at the work site at OUCC, from registered access recordings and statistical calculation.

5. Statistical data does not include commuting accidents.

6. Definition of high-consequence injury: According to Article 37 of the Occupational Safety Law, an occupational accident must be reported to the labor inspection agency within 8 hours.

7. No case of occupational disease sustained by "Implementation Measures for Occupational Disease Identification Operations of Labor Occupational Accident Insurance" in 2023.

8. In 2023, an occupational disaster occurred in which one person was injured and hospitalized. The report was completed within 8 hours of the incident, and investigation, analysis and records were carried out in accordance with regulations. The control measures taken to reduce the risk were also evaluated, and the risk after control was confirmed to be Level 5 (acceptable risk, maintaining existing safety and health controls, continuous monitoring).

Better Communication with Workers to Improve Occupational Safety and Health

OUCC followed the “G0300-WI-007 Guideline for Consultation and Participation of Workers and Occupational Safety and Health Committee Management” to reach internal consensus, and to establish safety and health management obligations and regular bilateral communication channels for internal employees, external contractors and the relevant stakeholders.

Stakeholders Contactors

- Mr. Chen/Ms. Chang

- E-mail: ESG@oucc.com.tw

SHE Contactors

- Mr. Yeh/Mr. Wu

- E-mail: she@oucc.com.tw