Zero Accidents in Transportation

Most of the chemicals in Taiwan rely on road transportation, but the lack of road planning for chemical transportation within the small geographical environment narrowly populated, any accident may immediately endanger the lives and property of the people nearby and cause significant losses to enterprises.

Therefore, OUCC attaches importance to the establishment of a transportation safety mechanism and fulfills its responsibility as a gatekeeper for transportation safety. There were no serious chemical leakages in 2023.

Transportation Risk Assessment

OUCC outsources all of its product transportation to external tanker truck operators. The main risk of chemical transport is traffic accident. Crashed or overturned truck may lead to chemical spills, endangering the lives and properties of truck drivers, road users, rescuers, nearby residents, and the wreck of environment, which shall incur tremendous social costs.

The direct cause triggering the hazardous substance leakage can be divided into four factors: human error, vehicle failure, storage facility, road and environment.

Transportation Risk Factors

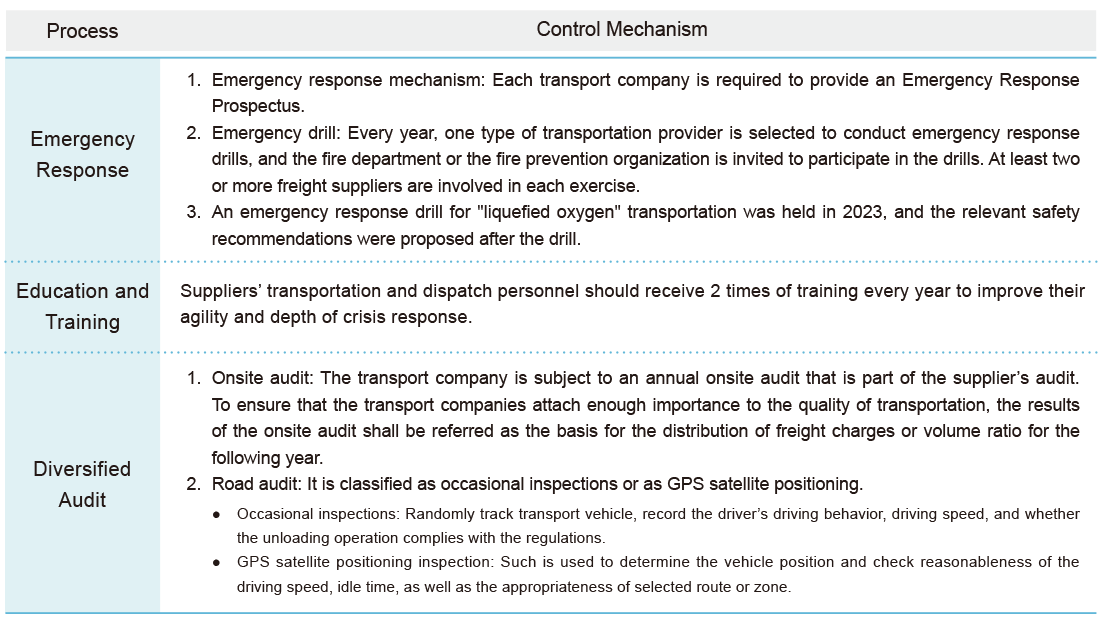

Zero Transportation Accident - Adopting Tighter Transport Control Practices

We develop strict management standards to ensure that freight suppliers jointly fulfill their security commitments since all the tanker transportation in OUCC is outsourced. Apart from compliance with the requirements of the laws and regulations, we also ask our freight suppliers to include the "Risk Factors" in the emergency response mechanism, and continue to improve the safety management system based on the past disaster reviews or potential risk analysis.

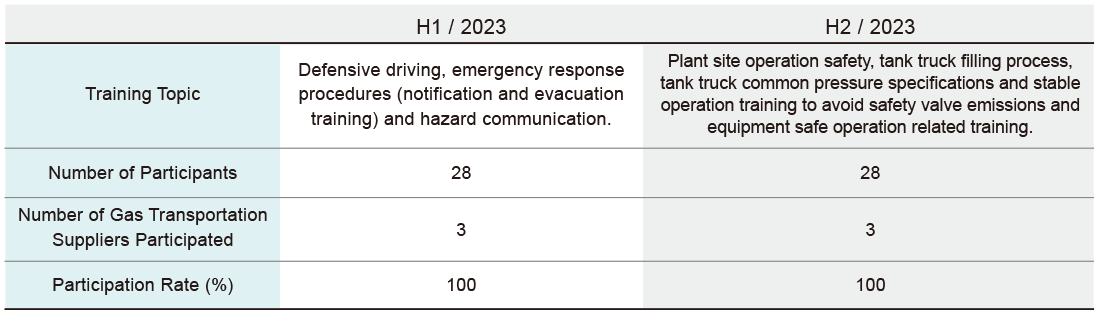

OUCC also makes use of case-collected information to improve the depth of crisis response in the supplier transportation personnel and to create a win-win situation for contractor and the company through the promotion of regular education and training for the drivers and freight suppliers.

Education and Training Results for the Gas Supplier Transportation Personnel

1. Before entering the plant, all drivers must have their temperature taken at the guard’s office. Anyone with a temperature above 37.5˚C will be denied entrance.

2. Contractors, subcontractors, drivers, etc., must wear masks at all times when they are at the plant premises.

3. Contractors, subcontractors, and drivers are prohibited from entering indoor space such as control room, office, warehouse, etc.

4. At the weigh station, drivers are required to sanitize their hands. Anyone who refuses to comply will be barred from continuing the operation.

5. Anti-pandemic measures such as Health Declaration Statement, Temperature Taken, and Social Distancing APP must be implemented before entering the plant premises.

6. The five rules of implementation include zero contact, visual confirmation of document, minimal conversation, keeping a safe distance and frequent sanitization.

7. During a severe epidemic, guests or contractors are prohibited from entering the plant premises for non-emergency events.

Field Pipeline Maintenance Operation and Management

OUCC formed the "Pipeline Maintenance Operation Team" to actively manage the pipeline-related business, including the establishment and management of pipeline diagrams, monitoring the current status of pipeline operations, conducting pipeline surveys, contingency drills, joint defense organization maintenance, and reviewing the management of pipelines out of OUCC to comprehensively control the inspection, testing, and maintenance status, so as to reduce the risks of the external pipelines.

Stakeholders Contactors

- Mr. Chen/Ms. Chang

- E-mail: ESG@oucc.com.tw

SHE Contactors

- Mr. Yeh/Mr. Wu

- E-mail: she@oucc.com.tw