Sustainable Supply Chain Management

To ensure the integrity and sustainability of business cooperation, OUCC has set up management policies such as "Rules Governing Suppliers" and "Environmental Safety and Health Policy" for supplier management. Suppliers must comply with the “Petrochemical Industry Code of Conduct,” ensuring that our suppliers comply with the relevant regulations, set higher environmental and occupational safety and health standards for the petrochemical industry, and build a solid and sustainable chemical supply chain.

- Before contract signed:review the "Supplier ESG Survey Form" during the audit phase, and inform them to refer to OUCC’s code of conduct and publicize it to their internal employees.

- After contract signed: understand and evaluate the integrity management or code of conduct implementation status via the "on-site audit.”

① Strengthen Sustainable Communication and Promotion

To strengthen the awareness and execution of ESG of the suppliers and contractors, whom we have worked closely with on labor, health and safety, environment, management, and business ethics to establish a comprehensive supply chain mechanism, aiming to lead supplier partners to commit to sustainability.

We proactively communicate with our suppliers, encourage them to enhance their sustainability management in breadth and depth, and make every effort to contribute. In the future, we will continue to maintain a good partnership with our suppliers, and actively invite our suppliers to respond to social welfare activities and join hands as a positive force in society.

② Sustainable Management Mechanism

To ensure that suppliers can understand and assist OUCC to strive for supplier sustainable development, we have designed a CSR self-assessment questionnaire for all our new suppliers, who are required to sign a letter of commitment, so to join us in a commitment to ESG and its implementation.

Note: 2023 Supplier Implementation Ratio = number of suppliers who signed the commitment in 2023 / total number of suppliers in 2023.

③ Evaluation Management Audit

This OUCC audit process includes record and on-site evaluations to ensure that suppliers are complied with all the relevant laws and regulations. Existing suppliers must receive and complete an annual evaluation, which consists of company management, quality, delivery time, price, service, and environmental safety. Suppliers will only be listed as qualified only if their rating score reached a specific standard.

Should an evaluation or material incident occur that rated disqualification and resulted in damage to the company’s reputation, labor safety, product quality, or manufacturing operation, the supplier would be listed as disqualified and suspended. In 2023, 718 trading suppliers underwent written evaluations with 2 disqualified, and the qualification rate is 99.7%.

The flammable, explosive and sometimes very toxic nature of chemicals carried by tankers makes their transportation a high-risk operation that can be hazardous. Negligence can lead to serious disaster. An accident can cause loss of life or serious injury, as well as damage to people’s property and severely impair the image of the company.

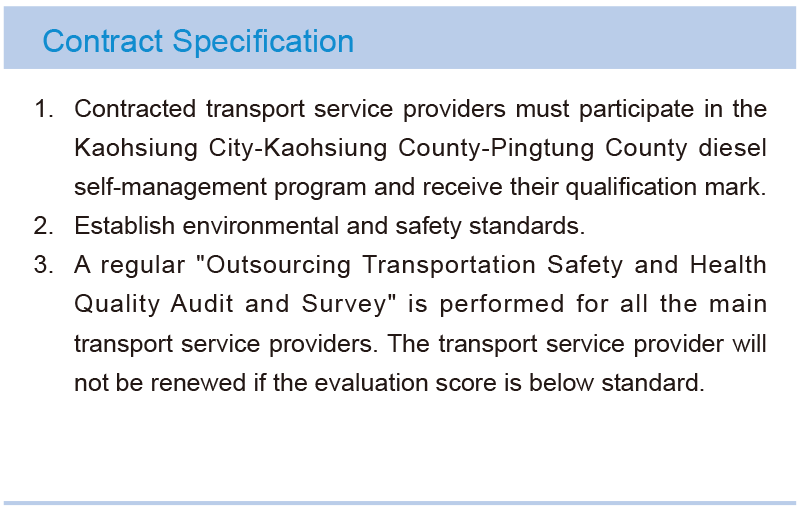

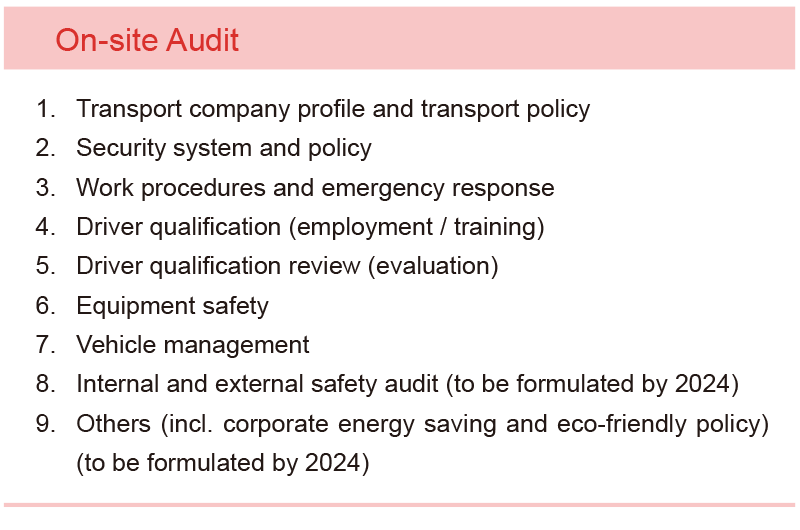

OUCC continues to strengthen transportation safety and crisis management capabilities through contracts and audit mechanisms with outsourced transportation providers, and to ensure the safe transportation of chemicals. In 2023, a total of 7 transportation suppliers signed the "Environmental Safety and Health Policy Handbook" and agreed to undergo on-site audits. By the end of the year, all of them successfully completed the audit with a 100% pass rate.

Management Results

All the contracted tankers of OUCC have passed the inspection performed by the National Accreditation Body. To enhance comprehensive safety management, we continue to communicate with contracted tankers with the target of all forwarders completing the signing of the “Supplier’s CSR Commitment”. There are total 7 contracted tanker forwarders in 2023, with the obtainment of the international system as follows :

Note: Freight Delivery Ratio = transaction amount of contracted tanker with introduction of international management system in 2023 / total transaction amount of all contracted tankers in 2023.

Future Goal

In response to ESG management trend, contracted tanker or transport companies will be requested to follow environmental safety and other health-related matters stated in their contracts. They must obtain environmental management system accreditation or be free of any industrial safety accident within the previous five years. All suppliers are invited to participate in ESG management and development.

The short-to-medium-term planning is to phase out old tank trucks that are over 15 years old to improve transportation efficiency and reduce carbon emissions. We procured 10 new-model tractors of high-tech and way better fuel efficiency to replace 9 old-modeled ones in 2023.

The long-term plan is to promote the installation of tire pressure detectors on large vehicles (in-tire type, installed on some tankers for long-term testing,) and the system can effectively control the condition of tires to significantly reduce transportation hazards and prolong the service life of tires.

④ Enhance Safety Promotion

“Contractor Work Safety Rules” have been formulated to ensure the safety of personnel and equipment in the plant area. The rights and obligations of contractors working in the plant are specified in detail. One of the requirements is that all contractor employees entering the plant premises must be qualified and hold industrial safety certificates to ensure the safety of personnel as well as the work environment.

OUCC organizes the Contractor Safety Conference regularly to conduct two-way communication on safety matters through the meeting. The OUCC internal units will convey factory regulations, environmental safety operations main points, etc., and conduct co-experience sharing of the OUCC supervision and contractor management, which would be followed by the extemporary motions for problems discovered and improvements review to ensure the safety of the workplace.

⑤ Preference for Local Suppliers

In addition to its own production, OUCC prioritizes the procurement of its main raw materials such as ethylene, oxygen, ethylene oxide, liquefied ammonia and fatty alcohol from selected domestic suppliers and uses imports as the supplement. In 2023, local procurement of specialty chemicals amounted to NT$0.66 billion, accounting for 59%; local procurement of ethylene amounted to NT$3.94 billion, accounting for 80%; and local procurement excluding raw and auxiliary materials amounted to NT$1.23 billion, accounting for 98%, which effectively promoted economic development in Taiwan.

Note:- Local procurement of specialty chemical raw materials is defined as manufactured locally.

- Domestic suppliers are defined as manufacturers registered in Taiwan, conducting transactions in the local currency (New Taiwan Dollar, TWD).

- 2023 percentage of procurement amount from domestic suppliers = procurement amount from classified domestic suppliers in 2023 / total procurement amount in 2023 x 100%

⑥ Practice Green Procurement

OUCC practices green procurement and consumption. Procurement specifications are established, and equipment standards are set with prioritized products of energy-saving and water-saving labels or other government approval. For example, the energy efficiency of electrical motors must comply with CNS14400 IE3. To achieve electricity, water, and energy conservation through the green procurement process in 2023, the purchase of green-certified items, including LED lamps and IE3 specification motor rotating equipment, reached NT$13.47 million, with 100% green procurement rate of LED lighting and rotating equipment.

Zero Transportation Accident - Adopting Tighter Transport Control Practices

We develop strict management standards to ensure that freight suppliers jointly fulfill their security commitments since all the tanker transportation in OUCC is outsourced. Apart from compliance with the requirements of the laws and regulations, we also ask our freight suppliers to include the "Risk Factors" in the emergency response mechanism, and continue to improve the safety management system based on the past disaster reviews or potential risk analysis.

OUCC also makes use of case-collected information to improve the depth of crisis response in the supplier transportation personnel and to create a win-win situation for contractor and the company through the promotion of regular education and training for the drivers and freight suppliers.

Education and Training Results for the Gas Supplier Transportation Personnel

- Before entering the plant, all drivers must have their temperature taken at the guard’s office. Anyone with a temperature above 37.5˚C will be denied entrance.

- Contractors, subcontractors, drivers, etc., must wear masks at all times when they are at the plant premises.

- Contractors, subcontractors, and drivers are prohibited from entering indoor space such as control room, office, warehouse, etc.

- At the weigh station, drivers are required to sanitize their hands. Anyone who refuses to comply will be barred from continuing the operation.

- Anti-pandemic measures such as Health Declaration Statement, Temperature Taken, and Social Distancing APP must be implemented before entering the plant premises.

- The five rules of implementation include zero contact, visual confirmation of document, minimal conversation, keeping a safe distance and frequent sanitization.

- During a severe epidemic, guests or contractors are prohibited from entering the plant premises for non-emergency events.

Stakeholders Contactors

- Mr. Chen/Ms. Chang

- E-mail: ESG@oucc.com.tw

SHE Contactors

- Mr. Yeh/Mr. Wu

- E-mail: she@oucc.com.tw