Dominant Technology & Independent Production - Polyetheramine Series

Published date:2022/03/31

Issued by: Process Development Dept. of Technical & RD Center

Achievements of Raw Materials Integration Coupled with Catalytic Development and Process Technology - Ethyleneamine Series of OUCC Dominant Technology

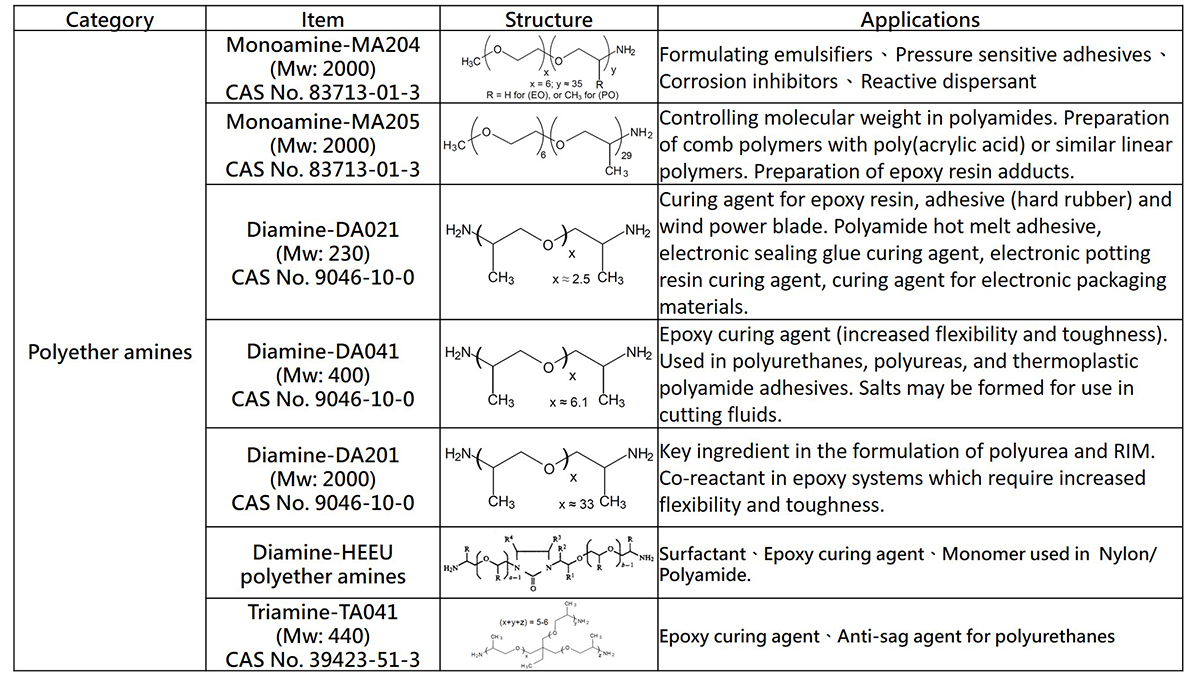

With wide applications, polyetheramine can be used in epoxy resin hardener, protective layer paint of transportation track, factory clean & waterproof coating, flooring paint, functional fiber, electronic component packaging materials and the like, while polyetherdiamine holds the key hardener to which the composite materials for the light-weighted wind blades cannot do without. In view of market demand, polyetheramines are mainly sold in developed industrial regions, such as France, the United Kingdom, Germany, China, Japan, South Korea, Singapore and Taiwan. Due to the advocacy of green energy in recent years, the installment of wind turbine has increased globally, coupled with the demand for weather-resistant and anti-corrosion coatings on account of the raising frequency of extreme weather, all of which resulted in the demand for polyetheramine. Referring to the forecast of the international institution, the average annual growth rate of increasing capacity of global grid-connected wind power in 2018~2028e is as high as 5.5%, the business opportunities of polyetheramine market are expected to be promising.

Raw Materials Integration Combining Catalytic Development and Process Technology, Accomplishment of a Mass Production Plant Starting from Scratch

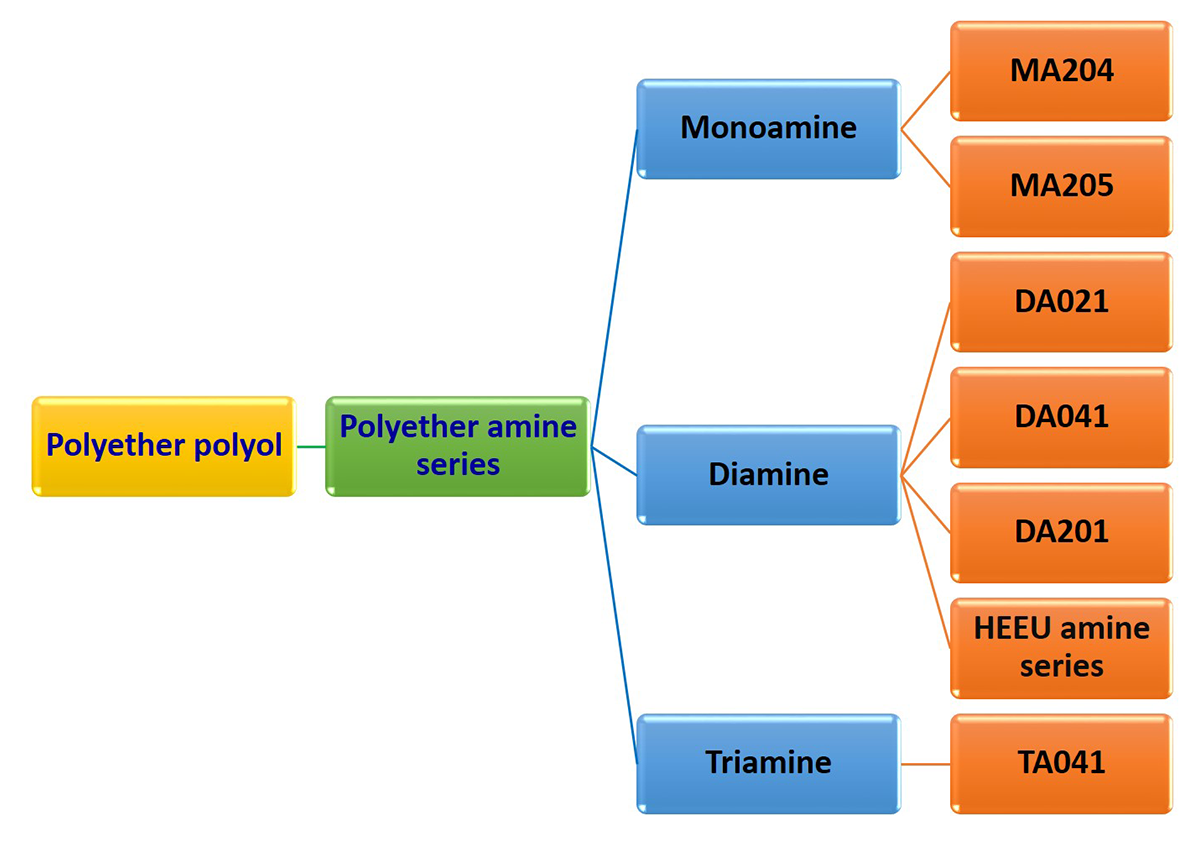

As polyetheramine is obtained through high temperature and high pressure reactions of polyether polyol and ammonia, the key to its mass production lies in the acquisition and operation of raw materials, catalyst technology and high-temperature & high-pressure process technology. In response to the government's offshore wind power energy policy and the independence of key materials, the polyetheramine plant, combining OUCC's edge in raw material, catalytic development, and engineering design, is scheduled to launch mass production in 2022, to fulfill customers demand.