OUCC Enters the Construction Chemical Industry Chain to Create a One-stop Upstream and Downstream Integrated Supply Model

Published date: 2021/07/26

Issued by: Construction Chemicals Department of SC Business Group

The enormous effect of Covid-19 pandemic in recent years has been challenging the used-to-be supply chain model, as the congested aerial/marine transportations with historical high freight rates remained alleviated, and the raw material prices fluctuated incessantly, which have constant conflict with our "common sense."

OUCC One-stop Supply Chain for Construction Materials

With an approx. total concrete volume of 40 milllion m3 annully in Taiwan, 160,000 tons of chemical admixtures will be needed for the concrete production process. In the past, domestic suppliers purchased PCE polycarboxylate copolymers mainly from China or South Korea, which were formulated and mixed into finished products prior to supplying to the downstream concrete industry.

In view of the concrete quality's susceptibility to chemicals within its suppy chain, and the lack of guiding public standards for quantification and standardization of chemical admixture quality, inflicting both tangible and intangible losses, OUCC decided to develop its own polymerization technology and proceed from the perspective of professional chemical synthesis to vertically integrate the production chain of the industry.

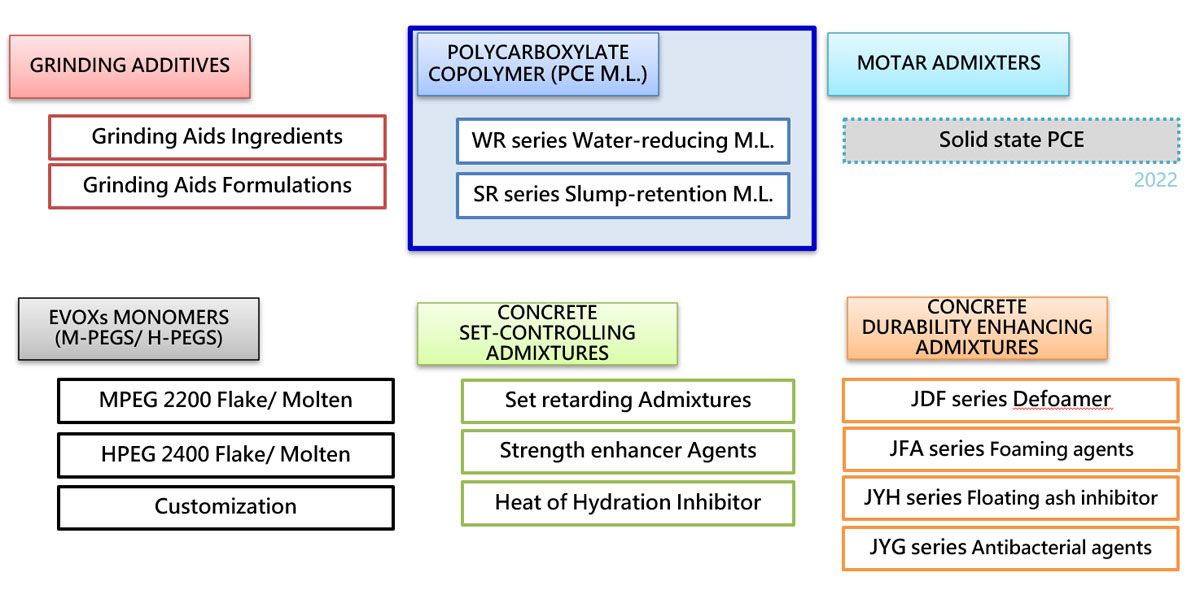

OUCC, as once the sole manufacturer of HPEG monomer in Taiwan, has mastered the key PCE polycarboxylate copolymer synthesis technology from years of experiences and research. Through the standardized operations, valuable instrument analysis, and big data management, the quantification standards for PCE polycarboxylate copolymer of OUCC have been established, providing domestic concrete industry supplier with a more secure and stable product level.

Despite the current foreign supply dominance of the special concrete admixtures, and the overall domestic gap in the comprehensive knowledge of such regard, the construction industry is confronting more severe challenges, accompanied by the rising awareness of environmental protection, and more stringent regulations, which can't be met by the traditional supply mode. Therefore, it is necessary to develop local special admixtures supply chain independently.

OUCC's developed admixtures can help increase more flexible workability of the concrete, including the early strength agents (SE series) for rapid hardening in winter, and the hydration heat controlling inhibitors (JHC series) for temperature control of the massive concrete.

Considering the quality of Taiwan's aggregates is changeable, and fly ash is likely to float during the concrete mixing process, affecting the appearance of concrete, OUCC has further developed the functional additive such as concrete appearance improvers (JYH series), defoamers (JDF series) and so on.

New Prospect of OUCC Construction Chemical

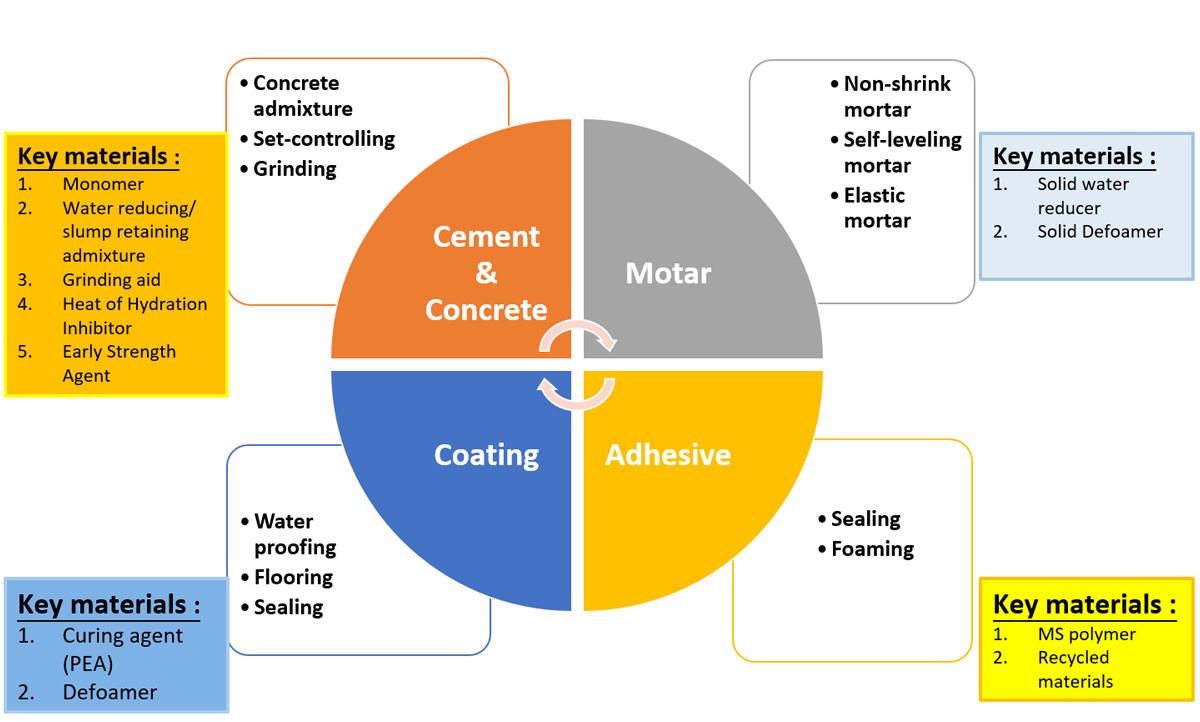

With the pivotal role as a domestic supplier of construction chemicals, OUCC's the newly established construction chemical department two years ago has integrated key construction chemicals and divided the main product categories into four sections, which are composed of cement and concrete-related additives, mortar material additives, coating-related curing agents & dispersants, and adhesion-related key materials.

In the future, we hope that OUCC can become a leading brand of domestic construction chemicals, further approach the terminal application market as expected, and fulfill the design needs of the industry, as well as guide domestic admixture suppliers in industrial upgrades.